In the dynamic world of fluid management, selecting the right equipment is crucial for operational efficiency and precision. The mini dosing pump, a compact and versatile solution, has gained significant traction across various industries, including pharmaceuticals, agriculture, and wastewater treatment. According to a recent report by Market Research Future, the global dosing pump market is projected to grow at a CAGR of 5.7% from 2021 to 2026, highlighting the increasing demand for reliable dosing systems. With their ability to deliver accurate and consistent flow rates, mini dosing pumps are becoming essential tools for businesses striving to enhance productivity and reduce waste. As the market evolves, understanding how to choose the right mini dosing pump tailored to specific needs is vital for maintaining operational standards and achieving cost-effective solutions. This guide aims to equip you with the essential knowledge and insights to make an informed decision when selecting a mini dosing pump for your applications.

Mini dosing pumps are crucial in various industries for precise liquid delivery. Understanding their key features can help you make an informed decision when choosing a pump. A report from the International Society for Pharmaceutical Engineering (ISPE) indicates that the global market for dosing pumps is expected to reach $4.2 billion by 2025, highlighting the growing importance of these devices. When selecting a mini dosing pump, consider factors such as flow rate, accuracy, and compatibility with the chemicals involved.

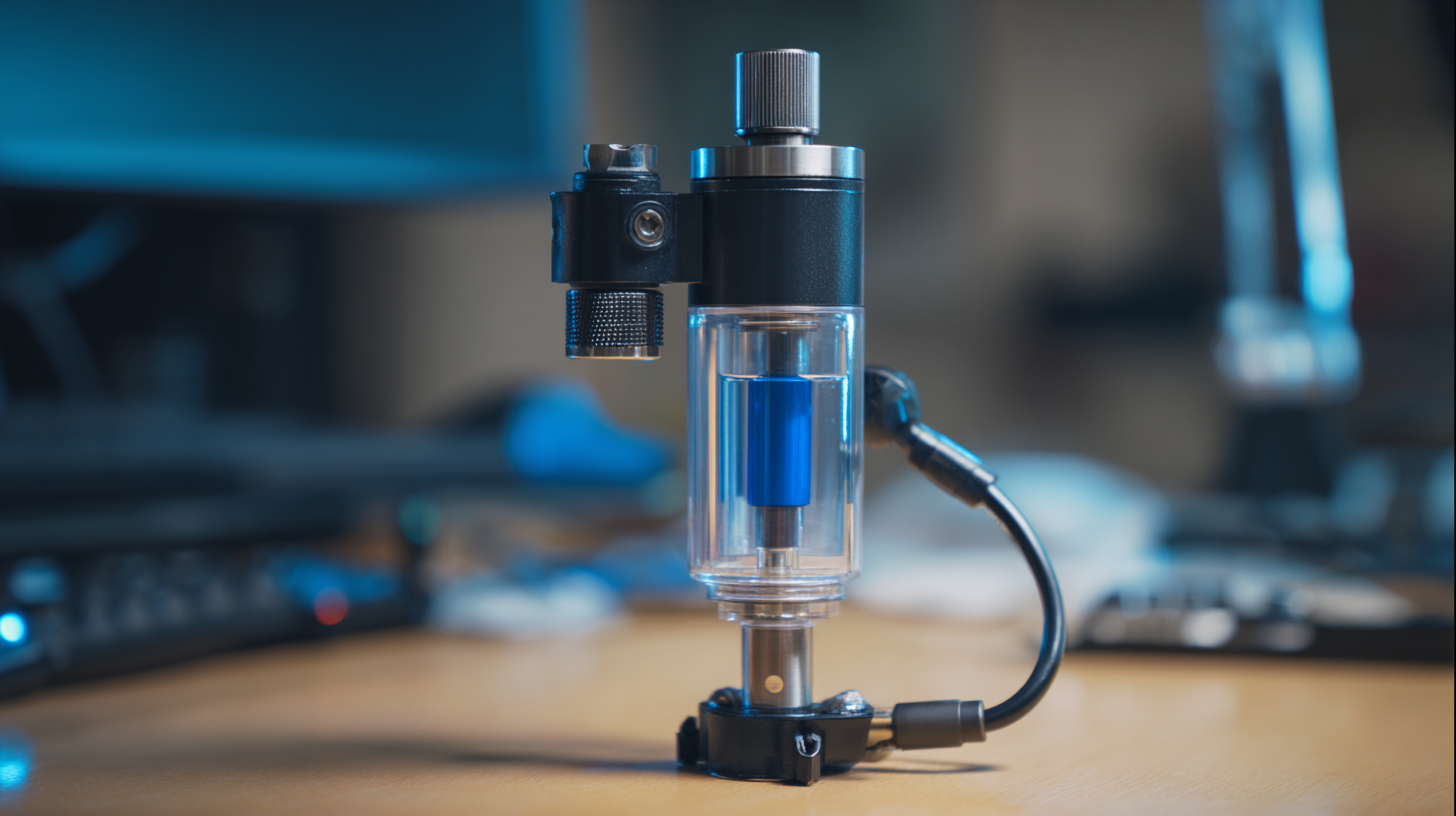

One critical technology in mini dosing pumps is the use of diaphragm materials like PTFE and EPDM, which enhance chemical resistance and longevity. According to a study by ResearchAndMarkets, pumps with advanced dosing mechanisms can achieve accuracy levels of ±1% or better. This precision is vital for applications in pharmaceuticals, food processing, and water treatment.

Tips: Always verify the pump's specifications and ensure it meets your application requirements. Additionally, consider the ease of maintenance and the availability of replacement parts, as these factors can influence long-term operational efficiency. Reviewing user testimonials can also provide valuable insights into the pump's performance in real-world scenarios.

When selecting a mini dosing pump, the significance of accuracy and precision cannot be overstated. Accuracy refers to how close the pump's dispensed quantity is to the desired value, while precision measures the pump's ability to replicate that quantity consistently over time. For applications requiring exact chemical proportions, such as in laboratories or industrial processes, a pump that excels in both accuracy and precision is crucial to ensure optimal performance and safety.

Identifying the right mini dosing pump involves evaluating your specific requirements against the capabilities of various models. For instance, if your operations demand frequent adjustments in dispensing rates, precision becomes vital. A pump with a high degree of repeatability will facilitate seamless adjustments, minimizing variability and improving overall process reliability. Additionally, many modern mini dosing pumps come with advanced features such as digital controls and real-time monitoring, enhancing their accuracy and allowing for meticulous calibration.

In any scenario where chemical dosing is involved, understanding the interplay of accuracy and precision can lead to more informed decisions. A pump that is accurate but not precise may still yield significant errors over time, while one that is precise but not accurate may mislead the entire dosing strategy. Therefore, careful consideration of these factors will align your choice of mini dosing pump with your operational goals, ensuring effective and safe chemical management.

When selecting a mini dosing pump for your application, one of the most critical factors to consider is material compatibility. Different substances, whether chemicals or fluids, can interact with pump materials in various ways, potentially leading to degradation or failure. For instance, if you're planning to dose acidic or caustic solutions, materials such as PVDF or PTFE are recommended due to their excellent chemical resistance. On the other hand, for food or pharmaceutical applications, FDA-approved materials like silicone or specific plastics are essential to ensure safety and compliance.

Another aspect to evaluate is the pump's intended application environment. High temperatures, pressures, or the presence of abrasive particles can significantly influence material selection. It's imperative to match the pump materials not only with the chemical properties of the liquid but also with the operational conditions. For example, while a neoprene diaphragm may work well for water-based solutions, it may fail quickly in a solvent-rich environment. Therefore, careful analysis of both chemical compatibility and environmental conditions is necessary to ensure that the mini dosing pump will perform reliably and efficiently in your specific application.

When selecting the ideal mini dosing pump, understanding the flow rate and pressure requirements is essential for achieving optimal performance. Flow rate, measured in liters per hour or gallons per minute, determines how quickly the pump can deliver liquid. This is crucial for applications where precise dosing is needed, such as in chemical processing or water treatment. Consider the specific demands of your system; if a higher flow rate is necessary to maintain operational efficiency, opt for a pump designed to meet those needs without compromising reliability.

Equally important is the pressure rating of the pump, which influences its ability to overcome system resistance and deliver fluids effectively. Each application has its unique pressure requirements, influenced by factors such as pipe size, length, and the physical characteristics of the fluid being pumped. It’s vital to choose a pump that can handle the maximum pressure your system might experience, ensuring that it operates smoothly and maintains accuracy in dosing. A comprehensive evaluation of both flow rate and pressure will lead you to the right mini dosing pump, tailored to ensure your processes run seamlessly.

| Pump Type | Flow Rate (L/h) | Pressure (bar) | Power Supply (V) | Weight (kg) |

|---|---|---|---|---|

| Diaphragm Pump | 10 | 2 | 230 | 2.5 |

| Peristaltic Pump | 15 | 1.5 | 120 | 3.0 |

| Gear Pump | 8 | 3 | 230 | 4.0 |

| Piston Pump | 5 | 4 | 230 | 5.5 |

| Lobe Pump | 12 | 2.5 | 240 | 6.0 |

When selecting a mini dosing pump, the balance between cost and quality is crucial. According to industry reports, the global market for dosing pumps is projected to grow at a significant rate, driven by the increasing demand for precise fluid management in agriculture and other sectors. Lower-priced options may seem attractive, but they often compromise on durability and performance, leading to higher long-term costs due to maintenance and replacement. Investing in higher-quality pumps can ensure reliable operation, which is essential in critical applications like water management, especially when integrating digital technologies to enhance efficiency.

Tips: When evaluating mini dosing pumps, consider their materials and construction. Pumps made from corrosion-resistant materials may have a higher upfront cost but can save money over time by reducing maintenance needs. Additionally, check for compatibility with digital monitoring systems that can improve water use efficiency in agricultural practices.

Furthermore, it is essential to analyze the specifications and features of various models. While lower-cost options may lack advanced functionalities, some higher-end pumps offer smart technology integration, enabling better monitoring and control. Understanding these aspects can empower buyers to make informed decisions and align their investments with their specific operational needs, maximizing both performance and cost-effectiveness.