In the ever-evolving landscape of industrial automation, the implementation of an Automatic Dosing System has become a pivotal strategy for enhancing efficiency and precision in chemical handling processes. According to a recent report by MarketsandMarkets, the global market for automatic dosing systems is projected to reach USD 3.4 billion by 2025, driven by the increasing demand for automation in sectors such as water treatment, food processing, and pharmaceuticals. As industries strive to minimize waste and optimize production, the need for accurate dosing solutions has never been more critical.

This article explores five smart dosing tips designed to streamline the deployment and operation of an Automatic Dosing System, ensuring not only compliance with regulatory standards but also significant cost savings and improved operational efficiency.

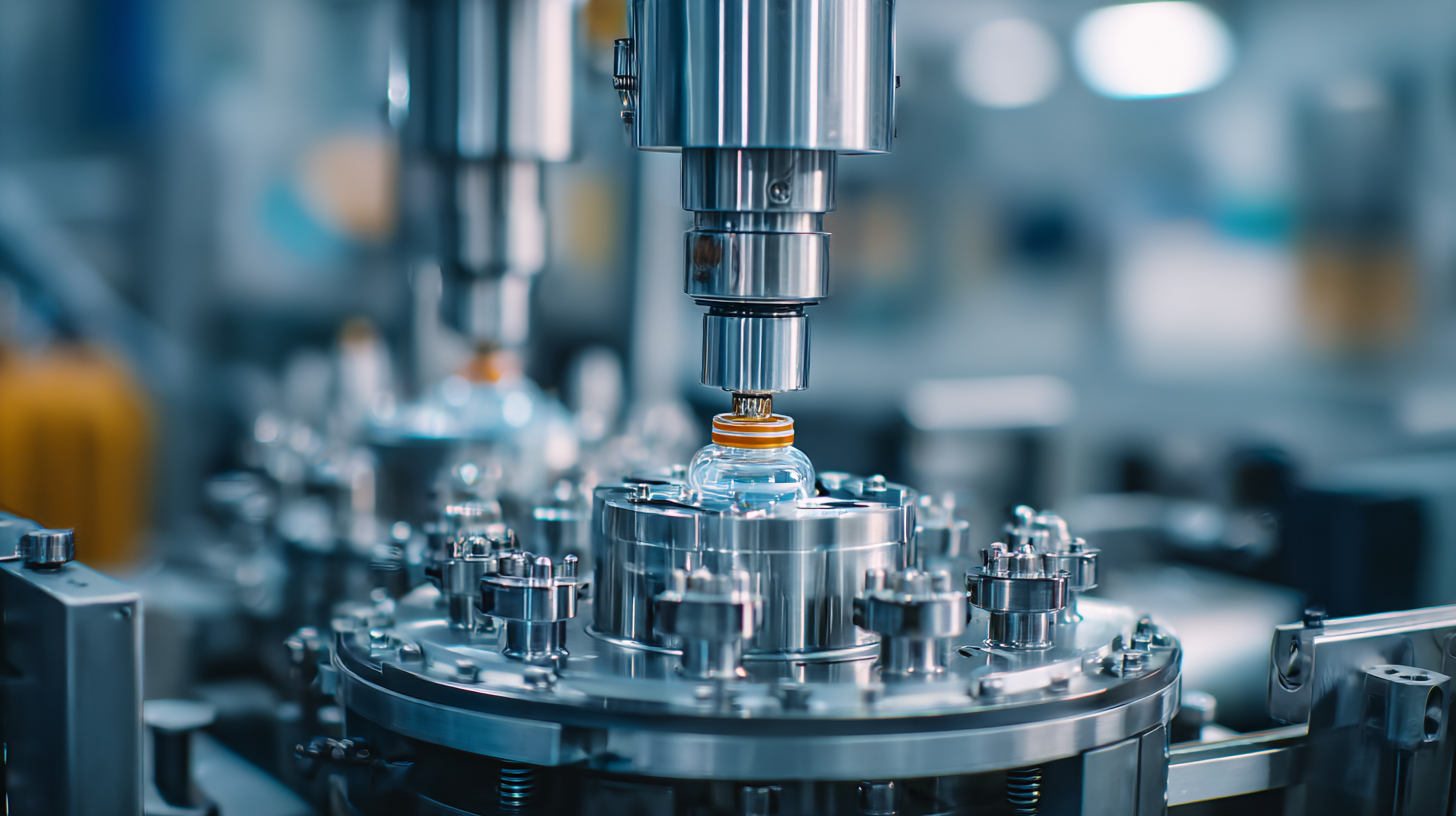

Setting up an efficient automatic dosing system requires a strategic approach that maximizes both performance and cost-effectiveness. One of the primary best practices is to calibrate the dosing pumps accurately to ensure precise chemical delivery. According to a report by the Water Research Foundation, improper dosing can lead to chemical overdosing by up to 30%, significantly increasing operational costs and potentially compromising system integrity. Regular calibration checks can help maintain dosages within optimal ranges, ensuring that the system runs efficiently.

Another essential practice is to monitor the flow rate and pressure of the dosing system consistently. The American Society of Mechanical Engineers (ASME) highlights that fluctuations in these parameters can result in inconsistent dosing, affecting the quality of the final product. By utilizing real-time monitoring technologies, operators can identify issues before they escalate, thereby maintaining efficiency. Implementing automated alarms and maintenance alerts also ensures that the system remains in peak condition, reducing downtime and enhancing overall productivity.

Effective calibration techniques are crucial for achieving accurate dosing in automatic dosing systems. Industries rely on precise measurements to ensure product quality and compliance with safety standards. One significant advancement in this area is the development of smart chemometrics-assisted methods, which enhance resolution and enable simultaneous determination of multiple substances, such as pharmaceuticals. These innovative techniques not only improve accuracy but also streamline the calibration process by effectively resolving overlapping spectra and related impurities, making them indispensable tools for industries handling complex mixtures.

Additionally, the growing emphasis on enhancing the performance of peristaltic pumps in pharmaceutical manufacturing underscores the importance of collecting comprehensive datasets. These datasets provide valuable insights into the accuracy of dosing outputs, allowing for optimization of dosing parameters. As industries strive for greater efficiency and reliability in their operations, leveraging these advanced calibration techniques and robust datasets becomes imperative. The integration of these elements not only ensures adherence to industry standards but also enhances overall production efficiency, positioning companies to meet the increasing demands of the marketplace.

In the realm of automatic dosing systems, real-time performance monitoring is crucial for ensuring efficiency and accuracy. Cutting-edge software solutions leverage IoT-based sensors and big data analytics for instant feedback on dosing metrics. Such technologies allow operators to track performance continuously, identify inefficiencies, and make data-driven adjustments that enhance productivity. For instance, advancements in deep learning image recognition have shown promise in monitoring processes like coagulation-settling in water treatment, demonstrating how artificial intelligence can optimize dosing in various settings.

Moreover, the integration of hybrid prediction models offers proactive management of dosing parameters, significantly reducing the chances of errors in automated systems. These models can analyze trends and predict future needs, providing users with actionable insights that lead to customized and responsive dosing strategies. With the rise of individualized treatments in fields such as precision medicine, the ability to monitor and adjust dosing in real time is becoming increasingly vital. As industries adopt these innovations, the efficiency of automatic dosing systems will undoubtedly experience a transformative leap, benefiting both operational output and end-user satisfaction.

The integration of data analytics into automatic dosing systems has proven to be a game changer in enhancing operational efficiency. According to a report by the International Society for Automation (ISA), leveraging data analytics can reduce dosing errors by up to 30%, resulting in significant cost savings and improved product quality. By continuously monitoring performance metrics and chemical usage patterns, facilities can make informed adjustments to their dosing processes, thus optimizing resource allocation and minimizing waste.

Furthermore, real-time data tracking allows for predictive maintenance of dosing equipment, which can prevent downtime and costly repairs. A study published by the American Society of Mechanical Engineers (ASME) highlighted that systems equipped with predictive analytics experienced a 25% increase in operational uptime. By utilizing advanced algorithms to analyze trends and anomalies in dosing operations, companies can preemptively address issues, ensuring consistent performance and compliance with regulatory standards. This data-driven approach not only enhances efficiency but also provides valuable insights that drive strategic decision-making across the production lifecycle.

Regular maintenance of automatic dosing systems is crucial for ensuring their longevity and performance. According to a report by the International Society of Automation, nearly 30% of equipment failures in dosing applications stem from inadequate maintenance practices. Implementing a proactive maintenance schedule can reduce downtime and enhance operational efficiency by up to 15%. Essential strategies include routine inspections, calibration of dosing pumps, and monitoring chemical concentration levels to prevent potential discrepancies that could harm both the equipment and the processes they support.

Another key aspect of extending the lifespan of dosing equipment is proper cleaning and preventive maintenance. The European Chemical Industry Council suggests that failure to regularly clean dosing systems can lead to chemical residue buildup, which might cause improper dosing rates and significantly impact production quality. By adopting advanced cleaning technologies and regularly scheduled maintenance routines, facilities can diminish the risk of contamination and mechanical wear. Investing in staff training on best maintenance practices is also beneficial, as human error accounts for approximately 20% of all operational issues in dosing systems, as highlighted in the latest industry reports.