In recent years, the significance of Metering Dosing Pumps has surged within modern industrial applications, driven by the need for precision and efficiency in fluid management. According to a MarketsandMarkets report, the global metering pump market is projected to reach USD 7.75 billion by 2024, growing at a CAGR of 5.4% from 2019. This growth reflects the increasing demand for accurate dosing in various industries, including water treatment, chemicals, and pharmaceuticals. Metering Dosing Pumps play a crucial role in enhancing process control and optimizing resource usage, making them indispensable in achieving regulatory compliance and operational excellence. With advancements in technology, modern metering pumps offer improved features such as real-time monitoring and remote operation capabilities, thus redefining their application landscape. As industries continue to evolve, understanding the role of these pumps becomes essential for leveraging their full potential and driving innovation.

Metering dosing pumps play a pivotal role in enhancing industrial efficiency across various sectors. By precisely controlling the flow and dosage of liquids, these pumps ensure that substances are delivered accurately, thereby minimizing waste and optimizing production processes. Their ability to provide consistent and repeatable dosing allows industries, such as pharmaceuticals and chemicals, to maintain quality standards while reducing operational costs. This precision is essential for achieving both regulatory compliance and competitive advantage.

Metering dosing pumps play a pivotal role in enhancing industrial efficiency across various sectors. By precisely controlling the flow and dosage of liquids, these pumps ensure that substances are delivered accurately, thereby minimizing waste and optimizing production processes. Their ability to provide consistent and repeatable dosing allows industries, such as pharmaceuticals and chemicals, to maintain quality standards while reducing operational costs. This precision is essential for achieving both regulatory compliance and competitive advantage.

Tips: When selecting a metering dosing pump, consider the fluid characteristics, required flow rate, and the specific application demands. Regular maintenance and monitoring of pump performance can prevent downtime and extend the lifespan of the equipment.

Furthermore, the integration of smart technologies with metering dosing pumps can further streamline operations. Modern pumps equipped with IoT capabilities allow for real-time monitoring of flow rates and pressures, enabling operators to make informed adjustments swiftly. This adaptive control translates into enhanced productivity and efficiency, as companies can respond promptly to changing demands in their processes.

Tips: Investing in training for operators on the latest dosing technology can significantly improve system utilization and reduce errors. Leveraging data analytics can also help in predictive maintenance, ensuring that pumps are serviced before issues arise, thus maximizing uptime.

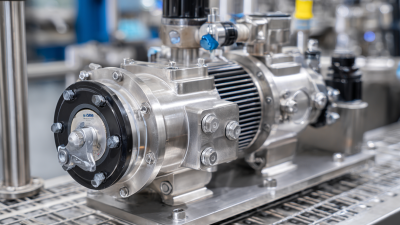

Metering dosing pumps are essential in modern industrial applications, particularly in chemical processes where precision and reliability are paramount. These pumps offer accurate dosing and flow control, ensuring that chemicals are mixed to the exact specifications required. According to a report by MarketsandMarkets, the metering pump market is expected to grow from $4.1 billion in 2021 to $5.6 billion by 2026, highlighting the increasing reliance on such technology to optimize operational efficiency and reduce waste.

One of the key advantages of metering dosing pumps is their ability to handle a wide range of flow rates and pressures. This versatility makes them suitable for various applications, from water treatment to pharmaceutical manufacturing. Furthermore, their advanced design minimizes the risk of chemical contamination, which is critical in sectors that require high purity standards. A recent study by ResearchAndMarkets indicates that nearly 30% of chemical processing companies are integrating automated dosing systems to enhance accuracy and maintain regulatory compliance.

Tips for choosing the right metering dosing pump include considering chemical compatibility, as different materials can affect performance and longevity. Additionally, regular maintenance is crucial for optimal operation—ensure that you perform routine checks on seals and connections to prevent leaks and downtime. Properly selected and maintained metering pumps can significantly contribute to operational success and cost savings in industrial applications.

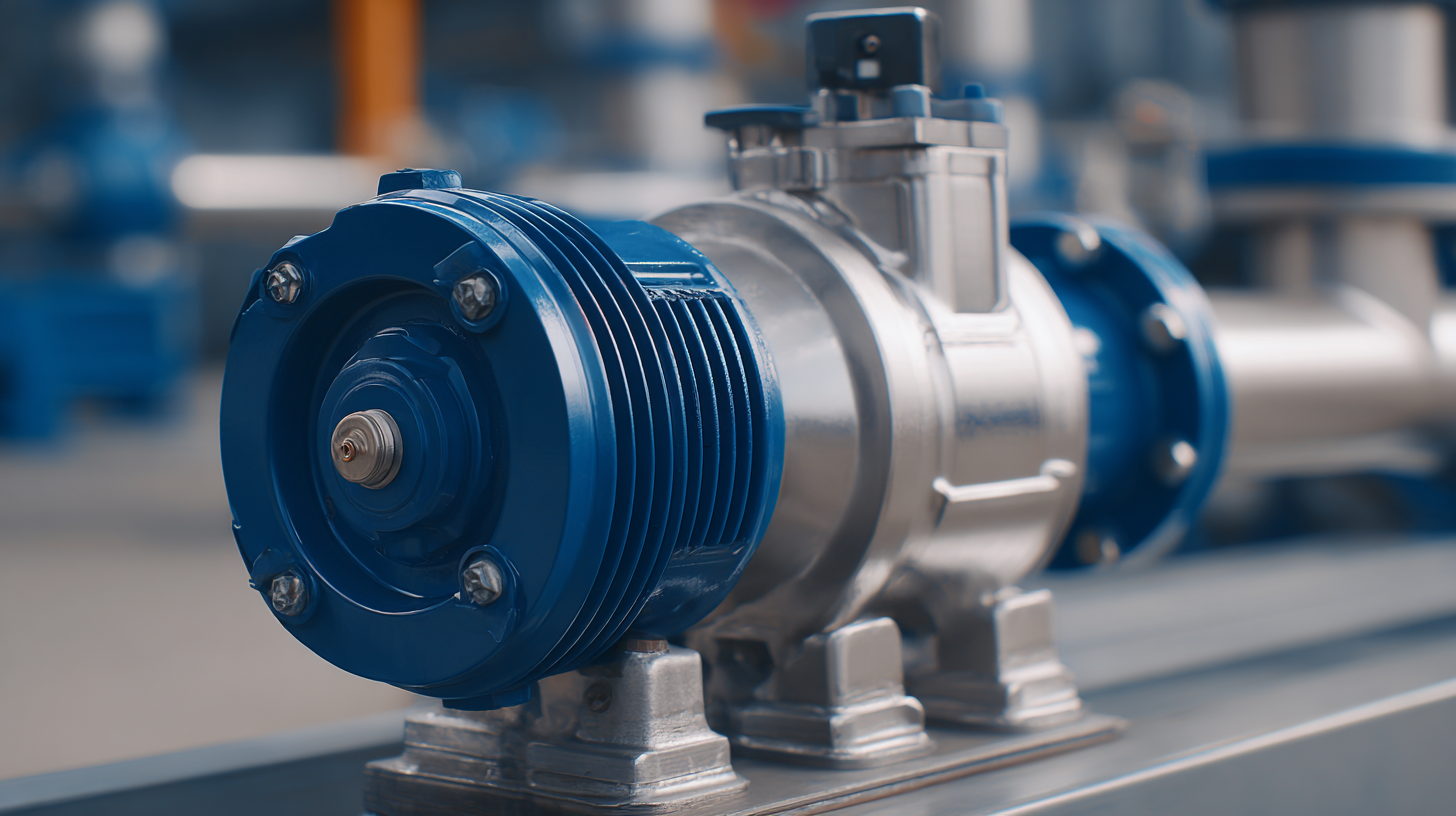

Metering dosing pumps play a crucial role in precision applications across various industries, including chemical manufacturing, water treatment, and pharmaceuticals. These pumps ensure accurate delivery of fluids, which is vital for maintaining product quality and process efficiency. According to a recent report by the International Society for Automation, precise dosing can improve process efficiency by up to 25%, leading to significant cost savings and reduced waste. This highlights the importance of metering dosing pumps in optimizing operational performance.

Tips: When choosing a metering dosing pump, consider the material compatibility and flow requirements specific to your application. Selecting pumps that can handle the chemical properties of your fluids will enhance reliability and minimize maintenance costs.

Furthermore, advancements in technology have led to the development of smart metering pumps equipped with digital controls and feedback systems. These innovations allow for real-time monitoring and adjustments, ensuring that dosing remains consistent under varying operational conditions. A study published in the Journal of Chemical Engineering indicates that integrating smart technology can reduce dosing errors by more than 30%. This level of accuracy is especially beneficial in industries where even minor variations can have significant repercussions.

Tips: Regular calibration and maintenance of metering pumps are essential for ensuring long-term accuracy and performance. Implementing a consistent maintenance schedule can prevent costly downtimes and ensure that your systems operate at peak efficiency.

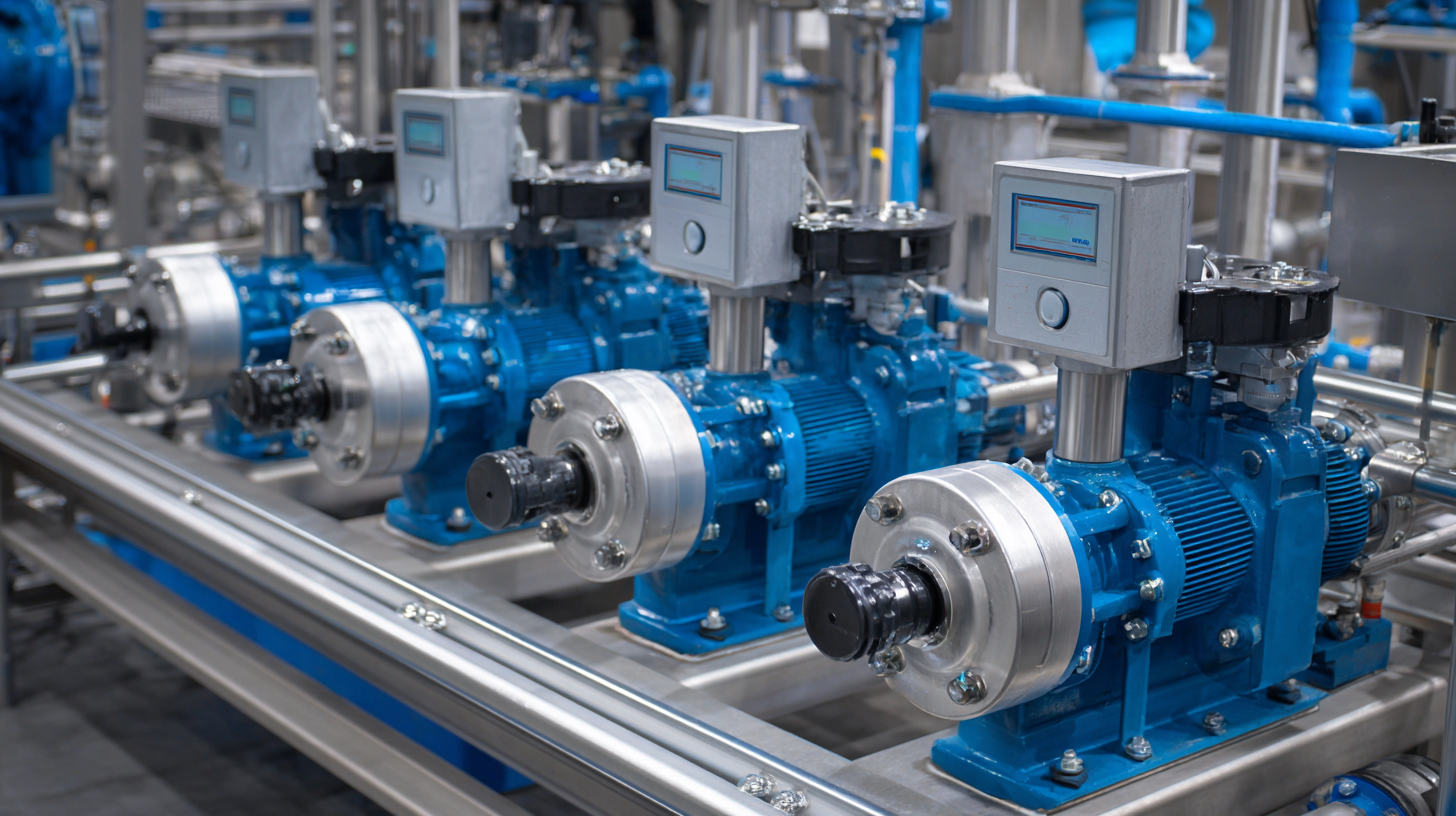

Metering dosing pumps play a crucial role in a variety of industrial applications, serving as essential tools for accurate fluid dispensing. Recent innovations in pump technology are significantly enhancing their performance, leading to increased efficiency and reliability. According to a report by Persistence Market Research, the global metering pumps market is projected to reach USD 5 billion by 2027, driven by the rising demand for precision in chemical processing and pharmaceutical manufacturing. This growth is largely attributed to advancements in control systems and materials used in pump construction that facilitate better flow rates and accuracy.

Innovative technologies such as smart metering systems and IoT integration are transforming how these pumps operate within manufacturing processes. For example, the implementation of advanced sensors and predictive maintenance algorithms allows for real-time monitoring and optimization of pump performance, thus minimizing downtime and reducing operational costs. A study by MarketsandMarkets emphasizes that the adoption of IoT-enabled metering dosing pumps will boost overall industrial productivity by up to 30% by 2025, underscoring the vital role that technological advancements will play in shaping the future of industrial fluid management.

The metering dosing pump market is on an upward trajectory, reflecting a significant growth trend that aligns with industrial demands. According to projections, the global dosing pump market size was estimated at USD 8.86 billion in 2024, with expectations to reach USD 13.96 billion, growing at a compound annual growth rate (CAGR) of 5.3% from 2025 to 2033. This growth indicates an increasing reliance on accurate and efficient dosing solutions across various sectors, where precision is paramount.

Additionally, the hydraulic dosing pump sector is experiencing a similar surge, forecasted to reach USD 4.5 billion by 2035, showcasing a remarkable CAGR of 4.0% between 2025 and 2035. These figures underscore the essential role of advanced pumping technologies in supporting industrial growth and innovation. As industries evolve, the integration of sophisticated metering solutions is vital not only for efficiency but also for sustainability goals, as accurate dosing minimizes waste and optimizes resource usage.