In today's rapidly evolving industrial landscape, optimizing fluid control systems is crucial for enhancing operational efficiency and ensuring precision. The advent of Metering Dosing Pumps has emerged as a game-changer in the realm of fluid management, offering unmatched accuracy and reliability. According to a recent industry report by MarketsandMarkets, the global market for metering pumps is projected to grow from $3.1 billion in 2021 to $4.1 billion by 2026, at a compound annual growth rate (CAGR) of 5.8%. This growth underscores the increasing demand for advanced fluid handling solutions across sectors such as pharmaceuticals, water treatment, and chemicals. By leveraging the capabilities of Metering Dosing Pumps, industries can achieve significant improvements in process efficiency, minimize waste, and reduce operational costs, paving the way for a more sustainable and productive future.

Metering dosing pumps play a crucial role in fluid control systems across various industrial applications, including chemical processing, food and beverage production, and water treatment. These pumps are designed to deliver precise amounts of fluid, ensuring accurate dosing that meets the stringent requirements of different industries. According to a recent report by the MarketsandMarkets research firm, the global metering pump market is projected to reach USD 6.1 billion by 2027, growing at a CAGR of 5.5%. This growth highlights the increasing demand for accurate fluid handling and the need for advanced metering solutions.

One of the key features of metering dosing pumps is their ability to enhance efficiency while minimizing waste. By using advanced control techniques, these pumps can adapt to varying flow rates and pressures, maintaining optimal performance in demanding environments. For instance, variable-speed metering pumps can help reduce energy consumption by up to 50%, offering significant cost savings.

**Tips:** When selecting a metering dosing pump, consider the specific viscosity and chemical compatibility of the fluids involved. Regular maintenance and calibration are essential to ensure optimal precision and longevity of the system. Additionally, utilizing pump automation can greatly improve operational efficiency and reduce human error in fluid control processes.

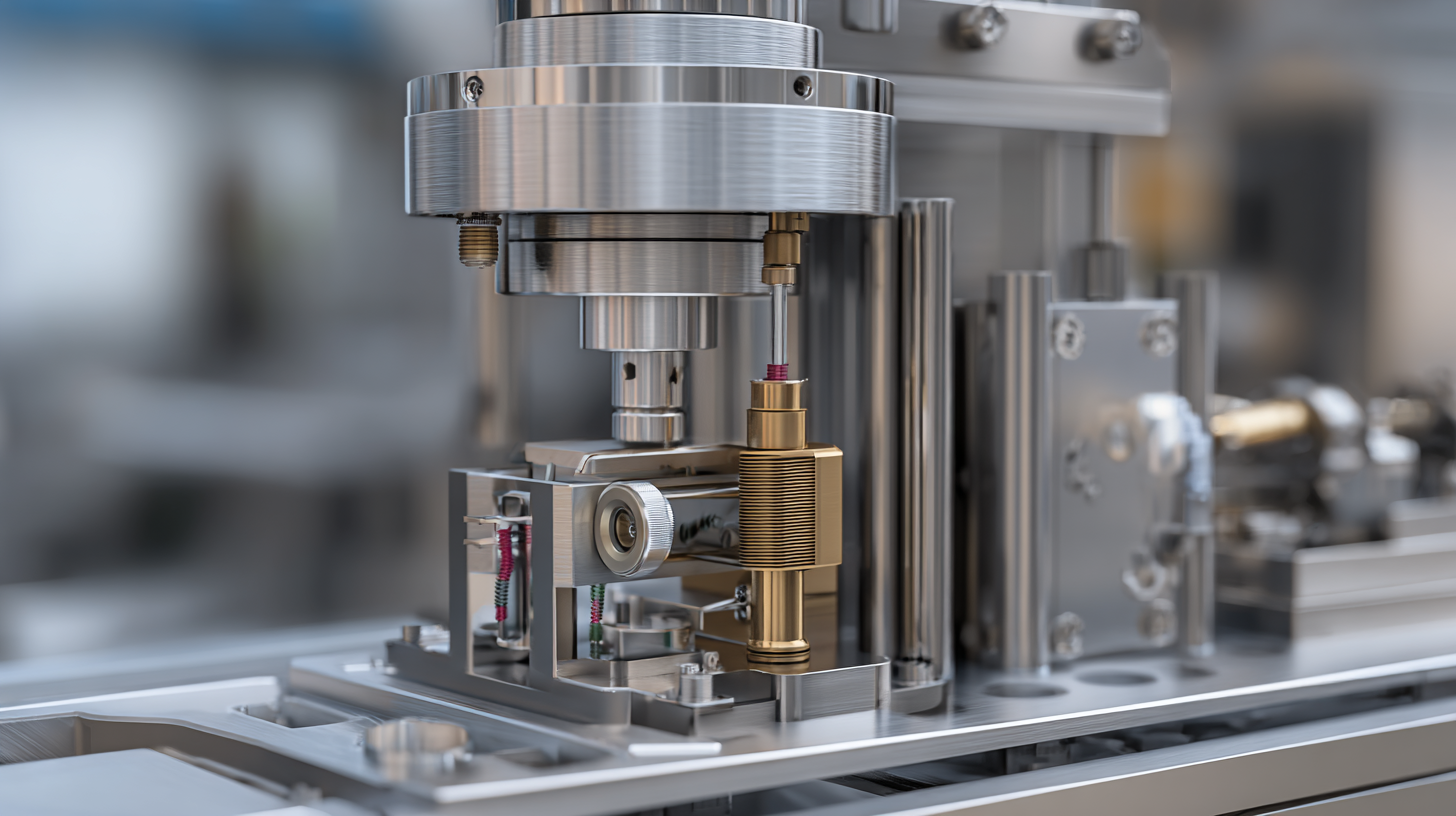

Metering dosing pumps have emerged as a pivotal technology for enhancing efficiency and precision in industrial fluid control. These pumps are specifically designed to deliver accurate volumes of liquids, ensuring that processes are carried out with minimal waste and maximum effectiveness. According to a recent report by MarketsandMarkets, the global metering pump market is projected to reach $8.21 billion by 2027, demonstrating a compound annual growth rate (CAGR) of 5.7% between 2022 and 2027. This growth is largely attributed to the demand for precision in industries such as water treatment, chemical processing, and pharmaceuticals.

One of the key features that set metering dosing pumps apart is their ability to deliver fluids at high precision, which is critical in applications where the exact dosage impacts product quality. For instance, a study from Frost & Sullivan highlights that metering pumps can achieve an accuracy rate of +/- 1%, significantly improving process outcomes compared to traditional pumping systems. Furthermore, the integration of advanced control mechanisms—such as digital interfaces and automation technology—allows for real-time monitoring and adjustments, ensuring that systems operate continuously at optimal levels. This not only leads to increased operational efficiency but also reduces the environmental impact by minimizing overuse of chemicals and resources.

Selecting the right metering dosing pump for your industrial application is crucial for optimizing efficiency and precision in fluid control. First, it’s important to evaluate the specific requirements of your application, including the type of fluid being pumped, its viscosity, and the desired flow rate. Consider environmental factors such as temperature and pressure, as these can significantly affect pump performance. Additionally, assess whether the fluid is corrosive or requires sanitary handling, as this will influence the material choice for the pump.

Next, assess the pump's operational features, such as control mechanisms and accuracy. For applications that demand precise dosing, look for pumps with advanced control technologies that offer digital interfaces and programmable settings. Moreover, consider the ease of maintenance and the availability of support services. A reliable metering dosing pump should not only meet performance demands but also minimize downtime through user-friendly maintenance procedures. By carefully analyzing these factors, you can ensure that you select a metering dosing pump that enhances operational efficiency and meets your specific needs.

The industrial landscape is increasingly recognizing the critical role of metering dosing pumps in fluid control, particularly for processes requiring high precision and efficiency. Recent industry reports highlight that optimizing the operation of these pumps can enhance overall system efficiency by up to 15%, significantly lowering operational costs and waste. Techniques like using advanced metering technologies, real-time monitoring, and predictive maintenance are pivotal in achieving desired performance levels.

**Tips for Optimizing Efficiency:**

- Implement smart sensors to monitor flow rates and provide real-time data for better decision-making, which can help reduce downtime by identifying potential issues before they escalate.

- Regularly calibrate your dosing pumps to maintain accuracy and ensure that you are dispensing the correct amounts, as small deviations can lead to significant cost increases.

Moreover, integration of automation in dosing systems has shown to decrease human error, with studies indicating that automating fluid management can reduce chemical consumption by up to 20%. By investing in modern metering dosing pump technologies and practices, manufacturers can capitalize on enhanced precision while driving down costs in their industrial applications.

Metering dosing pumps are essential in various industrial applications, ensuring precise fluid delivery. However, like any mechanical system, they can experience performance issues that can disrupt operations. Common problems include inaccurate flow rates, pulsation, and valve failures. These issues can often be traced back to improper calibration, wear and tear of components, or inadequate maintenance.

To troubleshoot these problems effectively, operators should first conduct a thorough inspection of the pump components, ensuring that each part is in good condition. Calibration checks should be performed regularly to maintain accuracy in flow rates. If pulsation is observed, it may be beneficial to assess the system for air leaks or obstructions in the lines. Additionally, regular maintenance, such as cleaning the valves and replacing worn-out seals and diaphragms, can significantly enhance the reliability and efficiency of metering dosing pumps. By addressing these common issues proactively, facilities can optimize their fluid control processes and maintain high operational standards.

| Application Industry | Pump Type | Flow Rate (L/hr) | Precision (% Variation) | Common Issues |

|---|---|---|---|---|

| Pharmaceutical | Diaphragm Pump | 10 | ±1 | Blockages, Calibration Issues |

| Chemical Processing | Gear Pump | 50 | ±2 | Seal Failure, Pressure Fluctuations |

| Water Treatment | Peristaltic Pump | 20 | ±3 | Tube Wear, Flow Rate Changes |

| Food & Beverage | Diaphragm Pump | 30 | ±1.5 | Validation Issues, Clogging |

| Personal Care | Diaphragm Pump | 5 | ±2 | Air Leaks, Performance Deterioration |