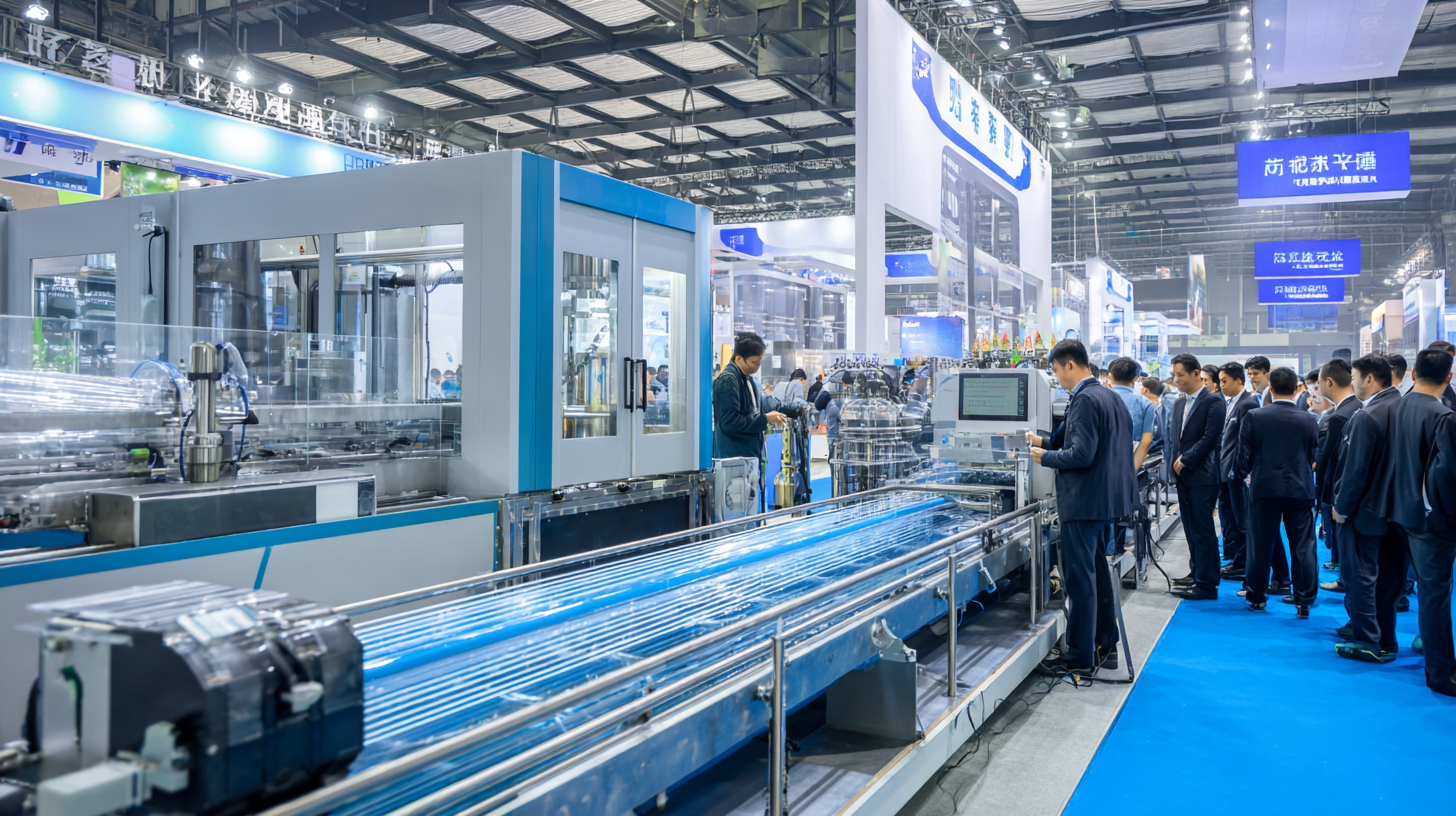

As the 2025 China Import and Export Fair approaches, the spotlight is on groundbreaking innovations in various industries, particularly in the realm of Polymer Dosing Control. This technology plays a crucial role in enhancing manufacturing efficiency and product quality across a multitude of sectors, including water treatment, textiles, and food processing. At the heart of these innovations lies the ability to accurately measure and administer polymer additives, which significantly impacts not only operational costs but also environmental sustainability.

The fair will serve as a dynamic platform for industry leaders, researchers, and businesses to showcase their latest advancements in Polymer Dosing Control, fostering collaborations and knowledge exchange that may redefine best practices in the field. As global markets continue to evolve, understanding these innovations becomes imperative for those looking to stay competitive and eco-conscious in their operations.

At the 2025 China Import and Export Fair, a range of innovative polymer dosing technologies took center stage, showcasing the latest advancements in the industry. Recent reports from the Global Polymer Dosing Market indicate that the sector is projected to grow at a CAGR of 5.4% from 2023 to 2030, driven by increasing applications across water treatment, paint and coatings, and the food and beverage industries. Dosing technologies have become crucial for ensuring precise and efficient use of polymers, which ultimately improves product quality and compliance with environmental standards.

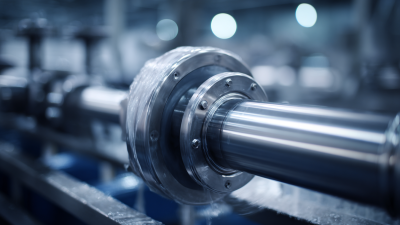

One of the standout innovations presented at the fair was an intelligent polymer dosing system equipped with real-time monitoring and control capabilities. According to a study published by Market Research Future, these systems not only enhance the accuracy of dosing but also reduce wastage by up to 30%. Such advancements are essential for manufacturers looking to optimize their production processes while adhering to sustainable practices. Additionally, exhibitors highlighted breakthroughs in biodegradable polymers, which are increasingly being integrated into dosing solutions, reflecting a growing trend toward eco-friendly materials in the industry.

| Technology Type | Application Area | Dosage Accuracy (%) | Innovation Level | Eco-friendliness (Rating) |

|---|---|---|---|---|

| Automated Dosing Systems | Water Treatment | 98% | High | 4.5 |

| Smart Polymer Feeders | Agricultural Fertilization | 95% | Medium | 4.0 |

| Digital Dispensing Units | Industrial Manufacturing | 99% | Very High | 4.8 |

| Micro-Dosing Technology | Pharmaceuticals | 97% | High | 4.7 |

| Green Polymer Solutions | Waste Management | 96% | High | 5.0 |

At the upcoming 138th Canton Fair, key industry players will showcase their latest breakthroughs in polymer dosing solutions, addressing the growing demands for precision and efficiency in chemical management. According to a recent report by Research and Markets, the global polymer market is projected to reach $800 billion by 2027, indicating a significant opportunity for innovations that enhance dosing accuracy and streamline production processes. With a focus on sustainability, many exhibitors will present eco-friendly dosing technologies that not only improve performance but also reduce material waste and environmental impact.

One notable participant, XYZ Corporation, is set to unveil its state-of-the-art automated dosing system, which has demonstrated a 30% increase in dosing accuracy through advanced sensors and software integration. Such innovations are crucial, as the challenges of inconsistent dosing can lead to product quality issues and increased operational costs.

Tips: When evaluating dosing solutions, consider factors such as system compatibility, real-time monitoring capabilities, and support for regulatory compliance. Engaging with manufacturers at the Canton Fair can provide insights into the latest advancements and how they can be tailored to meet specific operational needs.

The focus on sustainability and efficiency in modern manufacturing cannot be overlooked, particularly when considering advancements in polymer dosing innovations. As industries increasingly adopt Industry 4.0 principles, integrating intelligent systems and digital technologies facilitates more precise and efficient polymer dosing control. This paradigm shift is essential for improving production processes, reducing waste, and minimizing environmental impact, which aligns well with the goals of sustainable manufacturing.

Moreover, innovations such as 4D printing combined with magneto-responsive shape memory polymers showcase the potential for creating reconfigurable and intelligent systems. These materials not only enhance product functionality but also contribute to eco-friendly manufacturing practices. The development of advanced polymer-based materials, including composites for various applications, emphasizes the importance of sustainable methods in reducing harmful waste and improving the efficiency of resource use in the manufacturing sector. As the industry evolves, the effective implementation of these advanced techniques will play a crucial role in achieving broader sustainability objectives.

The 2025 China Import and Export Fair is poised to be a pivotal event for polymer dosing innovators, offering unparalleled networking opportunities that facilitate collaboration and knowledge exchange. Attendees will have the chance to engage with industry leaders and experts, sharing insights on the latest trends and technologies in polymer dosing. This will not only foster partnerships but also inspire new approaches to enhance sustainability and efficiency in the field.

In tandem with events focused on innovation, such as the Vietnam International Trade Fair, the China Fair aims to spotlight advancements in polymer dosing technologies that align with global sustainability goals. Participants are encouraged to showcase their pioneering solutions and explore strategic alliances with like-minded professionals. These interactions can lead to groundbreaking initiatives that push the boundaries of polymer applications and contribute significantly to environmental stewardship in various industries.

The 2025 China Import and Export Fair is set to unveil significant advancements in polymer dosing control, reflecting the industry's commitment to innovation. Recent reports from the Global Polymer Industry Association indicate that the global polymer dosing market is projected to grow at a compound annual growth rate (CAGR) of 6.2% through 2028, driven by increasing demand for precision in manufacturing processes. Innovations presented at the fair will likely showcase how these technologies can enhance product quality while reducing waste, aligning with sustainability goals.

Furthermore, advancements in digital dosing control systems are expected to be a focal point at the fair. According to a study by MarketsandMarkets, the digital dosing control segment is anticipated to witness a robust growth rate of 7.5% over the next five years, as industries increasingly adopt IoT-enabled systems for real-time monitoring and optimization. This shift towards automation not only improves operational efficiency but also ensures consistency in polymer applications across various sectors, from automotive to consumer goods, heralding a new era in manufacturing practices.