The 138th Canton Fair in 2025 is set to be a pivotal event for unveiling the latest innovations in Polymer Dosing Control, a critical aspect of various industries, including wastewater treatment, pharmaceuticals, and food processing. According to a recent market study by ResearchAndMarkets, the global polymer dosing market is projected to grow at a CAGR of 5.8% from 2020 to 2025, driven by increasing demand for efficient handling of polymers in industrial applications. As companies strive to enhance production efficiencies and reduce operational costs, the integration of advanced dosing control technologies becomes essential.

This event will serve as a platform for industry leaders to showcase groundbreaking solutions that optimize polymer utilization, improve process sustainability, and adhere to stringent regulatory standards. Attendees can expect insightful discussions on emerging trends and best practices, positioning themselves at the forefront of innovation in Polymer Dosing Control.

The 138th Canton Fair 2025 offers a vibrant platform for showcasing innovations in polymer dosing control technologies, reflecting the industry's dynamic evolution. Recent reports indicate that the global market for polymer dosing systems is expected to grow by over 7% annually, driven by increasing demand across various sectors, including water treatment, construction, and manufacturing. This growth trajectory highlights the necessity for advanced dosing solutions that enhance accuracy, reduce waste, and improve process efficiencies.

Innovative technologies on display at the fair emphasize automation and smart control systems, which not only streamline operations but also ensure consistent product quality. For instance, advancements in real-time monitoring and feedback systems allow operators to adjust polymer concentrations dynamically, leading to impressive reductions in chemical usage by up to 20%, as per industry surveys. Manufacturers are increasingly turning to integrated solutions that combine dosing systems with data analytics to optimize performance and minimize environmental impact.

**Tips:** When considering polymer dosing systems, look for features such as automated calibration and remote monitoring capabilities. These can significantly enhance operational efficiency and provide better insight into chemical usage patterns. Networking with industry leaders at the fair can also provide valuable insights into emerging trends and best practices for implementation.

At the 138th Canton Fair in 2025, the spotlight on polymer applications and dosing systems reveals significant industry trends that are reshaping the manufacturing landscape. One of the most notable trends is the increased integration of automation in dosing systems, which enhances precision and efficiency in polymer processing. Automated dosing not only minimizes material waste but also ensures consistency in product quality, thereby meeting the rising demands for sustainability in manufacturing.

Additionally, there is a growing emphasis on the development of smart polymers that respond dynamically to environmental stimuli. This innovation is driving the creation of advanced dosing systems that can adjust chemical compositions in real-time, allowing manufacturers to tailor products more effectively to specific applications. The convergence of IoT technologies and polymer dosing is enabling better data collection and analysis, resulting in optimized production processes and reduced operational costs. As these trends gain traction, they are expected to foster a more agile and responsive manufacturing environment, reflecting the evolving needs of the market.

| Application Sector | Dosing System Type | Innovation Highlight | Market Growth Rate (%) | Sustainability Impact |

|---|---|---|---|---|

| Water Treatment | Electromagnetic Dosing | Automated Control Features | 8.5 | High Efficiency |

| Construction | Pneumatic Dosing | Real-time Mixing Ratio Monitoring | 6.3 | Reduced Waste |

| Food Industry | Volumetric Dosing | Enhanced Hygiene Standards | 7.2 | Improved Quality Control |

| Pharmaceuticals | Peristaltic Pumps | Precision and Accuracy | 9.1 | Compliance with Regulations |

| Cosmetics | Inline Dosing Systems | Customizable Formulations | 5.0 | Eco-friendly Ingredients |

The exploration of sustainable practices within polymer dosing solutions is becoming increasingly crucial as industries seek to mitigate their environmental impact. The recent emphasis on green and sustainable pretreatment methods for cellulose extraction underscores the importance of utilizing biodegradable materials in polymer applications. By harnessing the potential of lignocellulosic biomass—primarily composed of cellulose, hemicellulose, and lignin—industries can develop eco-friendly polymer dosing solutions that not only enhance performance but also reduce ecosystem harm.

Moreover, the role of flocculant polymers in waste management has garnered attention, particularly regarding their effects on anaerobic digestion and dewatering processes. These polymers are vital for improving the efficiency of waste treatment while ensuring that the biological processes involved remain sustainable. Innovations in controlled-release fertilizers and the use of immobilized microbial consortia further highlight the industry's shift toward more sustainable practices. As these technologies evolve, they contribute to the development of solutions that address environmental concerns while supporting industry growth and sustainability goals.

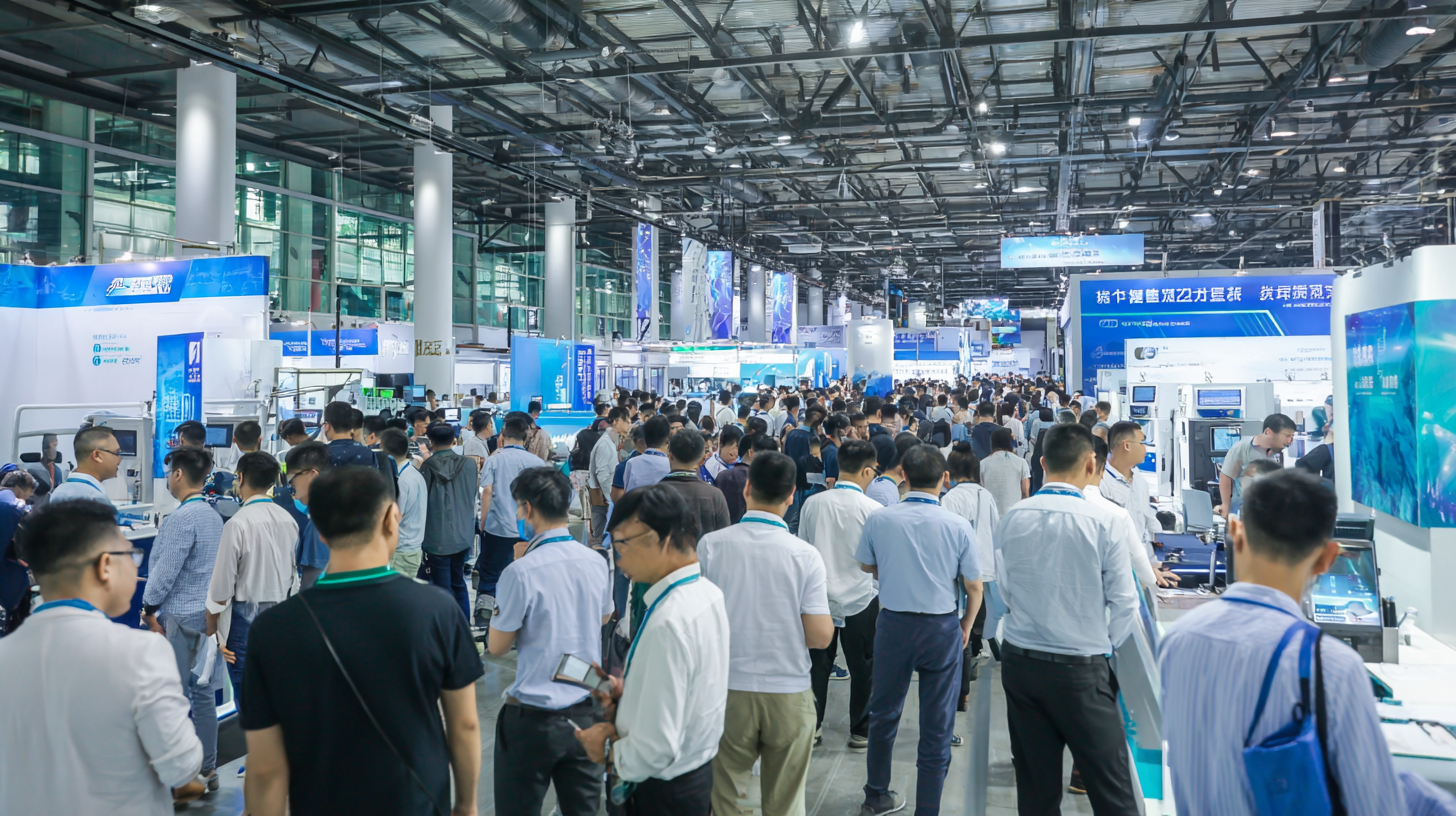

The 138th Canton Fair 2025 presents a unique platform for industry professionals to engage in meaningful networking opportunities and foster collaborations in the realm of polymer dosing control innovations. As businesses and innovators converge at this prestigious event, it becomes a melting pot for exchanging ideas and insights that could shape the future of the industry. Attendees will have the chance to connect with leading manufacturers, technology developers, and academic researchers, creating a vibrant ecosystem ripe for collaboration.

The 138th Canton Fair 2025 presents a unique platform for industry professionals to engage in meaningful networking opportunities and foster collaborations in the realm of polymer dosing control innovations. As businesses and innovators converge at this prestigious event, it becomes a melting pot for exchanging ideas and insights that could shape the future of the industry. Attendees will have the chance to connect with leading manufacturers, technology developers, and academic researchers, creating a vibrant ecosystem ripe for collaboration.

In addition to formal networking sessions, the Canton Fair encourages spontaneous interactions through workshops, panel discussions, and exhibition showcases. This environment not only enhances learning but also cultivates partnerships that can lead to groundbreaking developments in polymer dosing technology. By engaging with peers and exploring potential synergies, participants can tap into new markets and technologies, ensuring they remain at the forefront of industry trends. The fair's focus on collaboration and innovation makes it an essential destination for anyone looking to make significant strides in the polymer sector.

As industries shift towards Industry 4.0, the integration of advanced technologies in polymer dosing systems is becoming increasingly critical. Recent reports indicate that the global market for polymer dosing systems is projected to grow significantly, with an expected CAGR of 10.5% from 2023 to 2030. This growth is driven by the rising demand for precise and efficient chemical dosing in sectors such as wastewater treatment, oil and gas, and pharmaceuticals. Innovations such as automated, smart polymer dosing units enable industries to optimize resource usage, reduce waste, and enhance operational efficiency.

The role of polymer dosing in Industry 4.0 goes beyond mere automation; it encompasses data-driven decision-making and real-time monitoring. By leveraging IoT technologies, manufacturers can gain valuable insights into their dosing processes, allowing for predictive maintenance and minimized downtime. A recent study from the International Society of Automation highlighted that predictive maintenance can lead to a reduction of operational costs by up to 30%. The ability to adapt dosing in real time based on data analytics not only improves product quality but also aligns with sustainability goals, showcasing the pivotal role of polymer dosing systems in the future of industrial manufacturing.