Polymer dosing is a critical process in various industries, particularly in wastewater treatment, where the efficient use of polymers can significantly enhance flocculation and sedimentation performance. According to a recent report by the American Water Works Association, optimizing polymer dosing systems can lead to an improvement of up to 30% in sludge dewatering efficiency, reducing operational costs and increasing treatment capacity. Furthermore, the global polymer industry is projected to experience a growth rate of 5.6% annually, reaching a market size of $1,000 billion by 2025, reflecting the increasing demand for innovative dosing solutions. This highlights the necessity for industries to focus on maximizing the efficiency of polymer dosing systems. By employing advanced technologies and best practices, businesses can ensure optimal polymer usage, reduce waste, and achieve superior performance in their operations.

When evaluating the performance of your current polymer dosing system, it’s essential to conduct a thorough assessment based on industry benchmarks. Research from the Water Environment Federation (WEF) indicates that optimizing polymer dosing can lead to up to 50% reductions in polymer consumption while still maintaining performance levels in wastewater treatment processes. Regularly reviewing system metrics such as flow rates, mixing efficiency, and polymer activation can reveal inefficiencies that, when addressed, can significantly enhance the overall operation.

In addition to quantitative assessments, qualitative factors should not be overlooked. A study by the American Chemical Society found that operator training and system maintenance can directly impact dosing accuracy and performance. Implementing routine maintenance checks and training programs for operators can lead to more efficient polymer usage and improved system reliability. By integrating both data-driven insights and operator engagement, facilities can optimize polymer dosing systems, resulting in cost savings and enhanced operational performance.

This chart illustrates the performance metrics of polymer dosing systems based on various optimization strategies. The data represents average efficiency rates and performance scores before and after implementing these strategies.

When optimizing polymer dosing systems, several key variables significantly influence dosing efficiency. One primary factor is the polymer concentration, as the effectiveness of the dosing system is often contingent upon maintaining the optimal concentration for specific applications. If the concentration is too low, the desired flocculation or coagulation processes may not occur, leading to inefficient treatment. Conversely, excessively high concentrations can create operational challenges, such as increased viscosity, which can hinder pump functionality and accuracy in dosing.

Another critical variable is the mixing intensity within the dosing system. Adequate mixing ensures that the polymer is evenly distributed throughout the water or wastewater being treated. Insufficient mixing can result in localized areas of reduced polymer effectiveness, which compromises overall performance. Adjusting the mixing speed and duration can help achieve a uniform blend, allowing for more consistent dosing and enhanced operational efficiency. Additionally, monitoring and controlling parameters such as temperature and pH can further optimize polymer performance, as these factors can significantly impact polymer behavior and interaction with contaminants in the water.

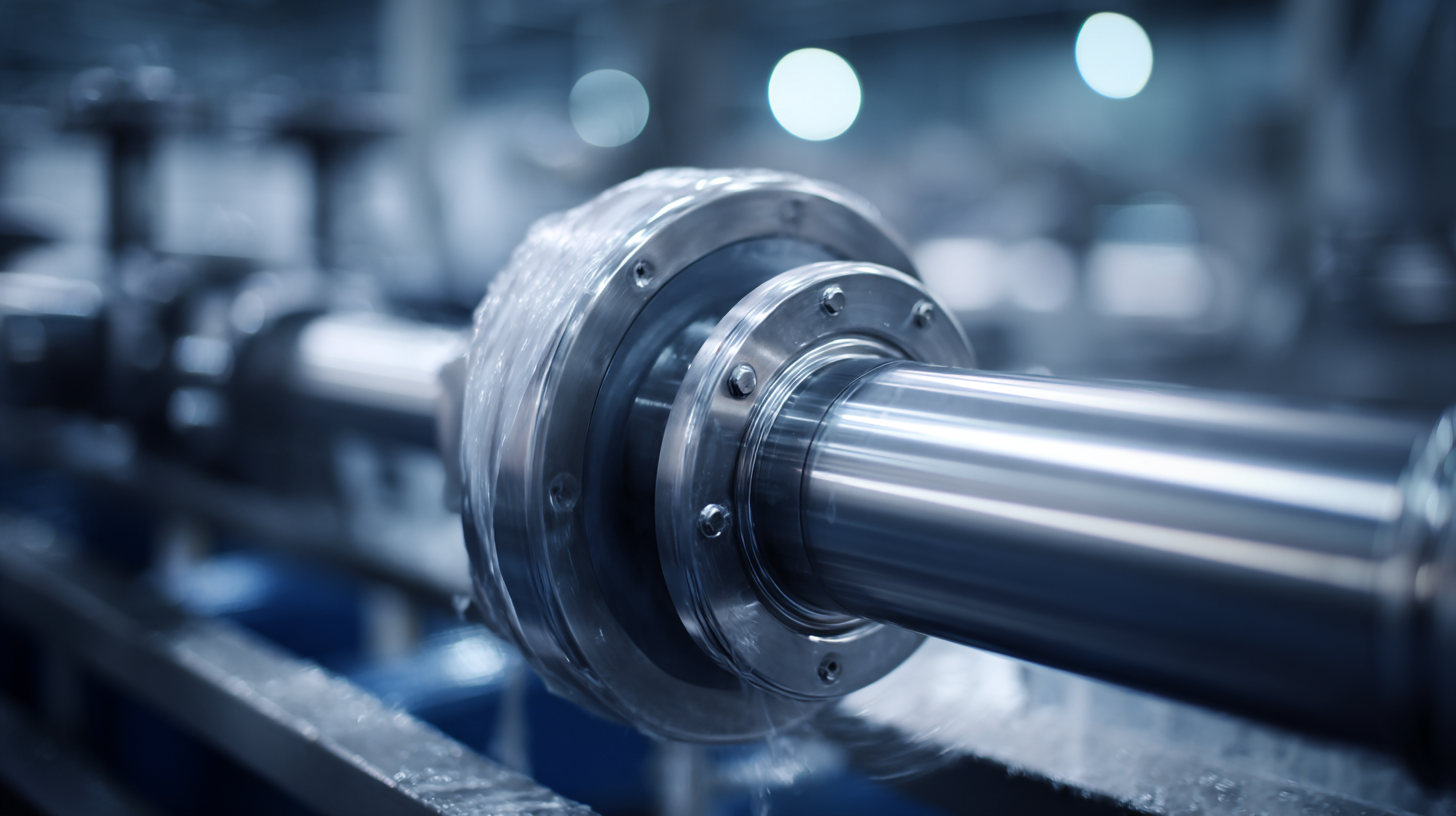

Optimizing polymer mixing and activation is crucial for maximizing the performance of polymer dosing systems. One effective technique is employing advanced mixing technologies, such as high-shear mixers, which ensure that polymers are uniformly blended into the solution. These mixers create powerful vortices that help in breaking down polymer aggregates and enhancing solubility, leading to a more consistent polymer distribution. Additionally, the use of inline mixing systems can significantly reduce mixing time and improve overall process efficiency by continuously blending the polymer solution as it moves through the system.

Another vital approach is to carefully control the activation conditions, including temperature, pH, and shear rate. Precise regulation of these parameters can improve polymer activation significantly, ensuring that the polymers reach their optimal performance state. Implementing real-time monitoring and automation can also aid in maintaining these conditions, allowing for immediate adjustments based on dynamic changes in the system. By focusing on these techniques for optimizing polymer mixing and activation, facilities can achieve better efficiency and performance in their polymer dosing systems, ultimately leading to enhanced outcomes in various applications.

Optimizing polymer dosing systems is crucial for enhancing both efficiency and performance. One vital aspect of this optimization lies in establishing best practices for maintenance and troubleshooting. Regular maintenance not only extends the lifespan of dosing systems but also ensures consistent performance. According to industry reports, systems that undergo scheduled maintenance can reduce downtime by up to 30%, significantly improving overall operational efficiency.

Troubleshooting is another key area that requires attention. Effective diagnosis of issues can save time and resources. Implementing advanced controls and modern pumping technology can improve the accuracy and repeatability of liquid dosing, decreasing the likelihood of errors. A recent study found that upgrading to automated systems can enhance dosing precision by as much as 15%, which is essential in applications where material performance directly correlates with dosing accuracy. By focusing on these maintenance and troubleshooting best practices, organizations can ensure their polymer dosing systems operate at peak performance, ultimately leading to better product outcomes and reduced operational costs.

The integration of automation in polymer dosing systems is vital for enhancing efficiency and performance. Automation not only streamlines the dosing process but also ensures precision in dispensing polymer materials. Advanced sensors and control systems allow for real-time monitoring and adjustments, reducing human error and inconsistencies that can occur in manual operations. By implementing automated solutions, operators can achieve a more stable process that maximizes the effectiveness of the polymers being used.

Furthermore, automated dosing systems provide valuable data analytics which can be leveraged to identify trends and optimize formulations. This data can help in fine-tuning the dosing parameters, ensuring that the right amounts of polymer are used at the right times, thus minimizing waste and reducing costs. As industries continue to evolve, the reliance on automated systems will increase, making it crucial for organizations to invest in these technologies to remain competitive and improve overall operational performance.