In the realm of fluid management, precision is paramount, especially in industries such as pharmaceuticals, chemicals, and food processing. According to a market research report from MarketsandMarkets, the global metering pump market is projected to reach $6.2 billion by 2025, driven by the increasing demand for accurate and efficient fluid control systems.

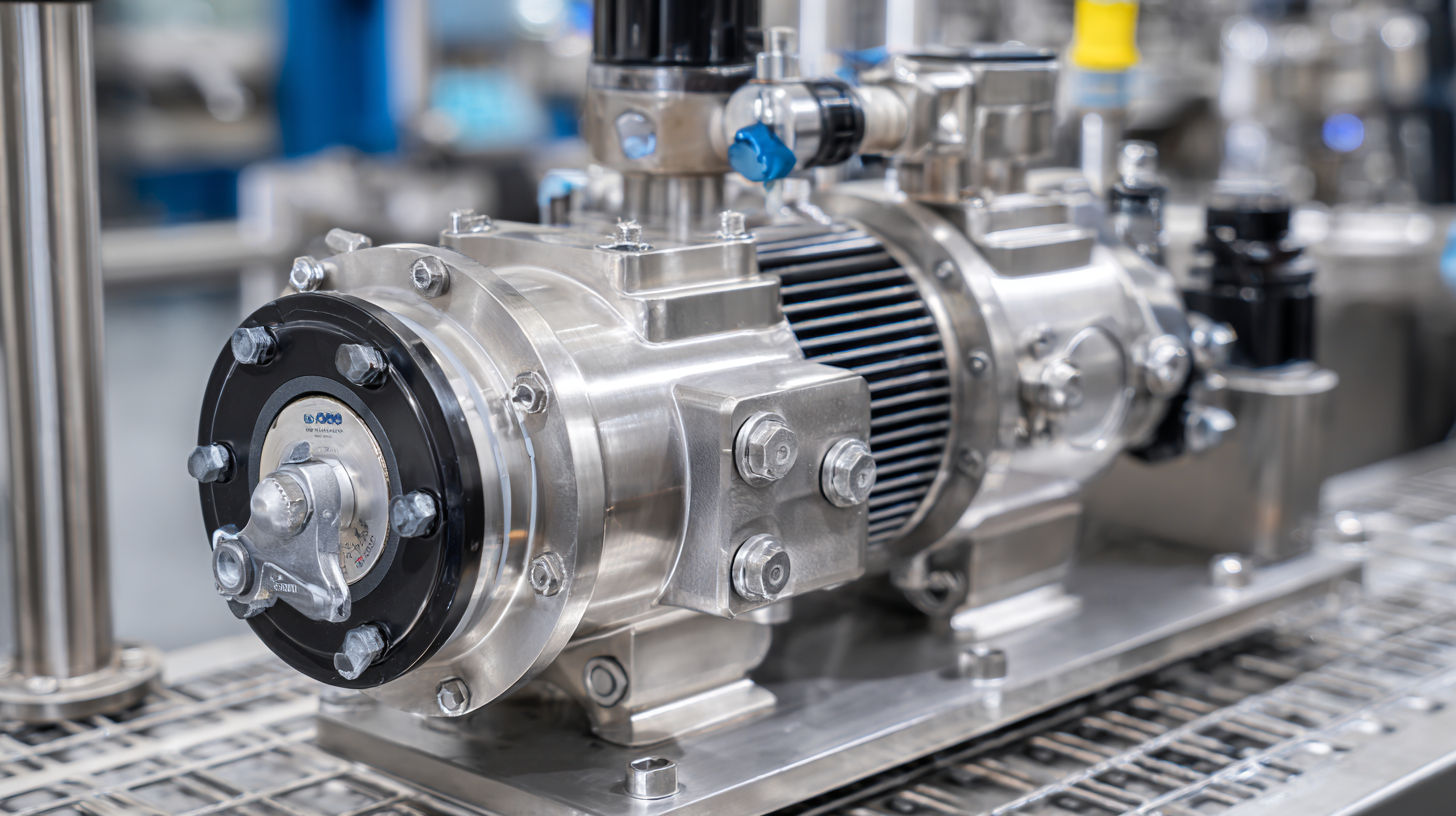

Metering dosing pumps stand out as the optimal choice for achieving precise fluid delivery, thanks to their ability to maintain consistent flow rates and minimize variability across applications. These pumps not only enhance process efficiency but also ensure compliance with strict regulations governing fluid handling.

This article will explore five compelling reasons why the metering dosing pump is the ideal solution for precision fluid control, positioning it as a critical component in modern industrial operations.

Precision in fluid control is paramount across various industries, particularly in sectors like pharmaceuticals, water treatment, and food processing. According to a report by MarketsandMarkets, the global metering pump market is projected to reach USD 9.5 billion by 2025, driven largely by the increasing demand for accurate dosing in manufacturing processes. This emphasizes the importance of employing technologies that ensure precise measurement and delivery of fluids.

Metering dosing pumps stand out in their ability to provide consistent, reliable performance critical to production efficiency. A detailed analysis from Grand View Research indicates that the growing complexity of fluid management has made precision dosing more essential than ever. These pumps allow for fine-tuning of flow rates, which minimizes waste and enhances product quality. By maintaining exact quantities, industries can adhere to stringent regulatory standards and optimize operational costs, which ultimately boosts profitability.

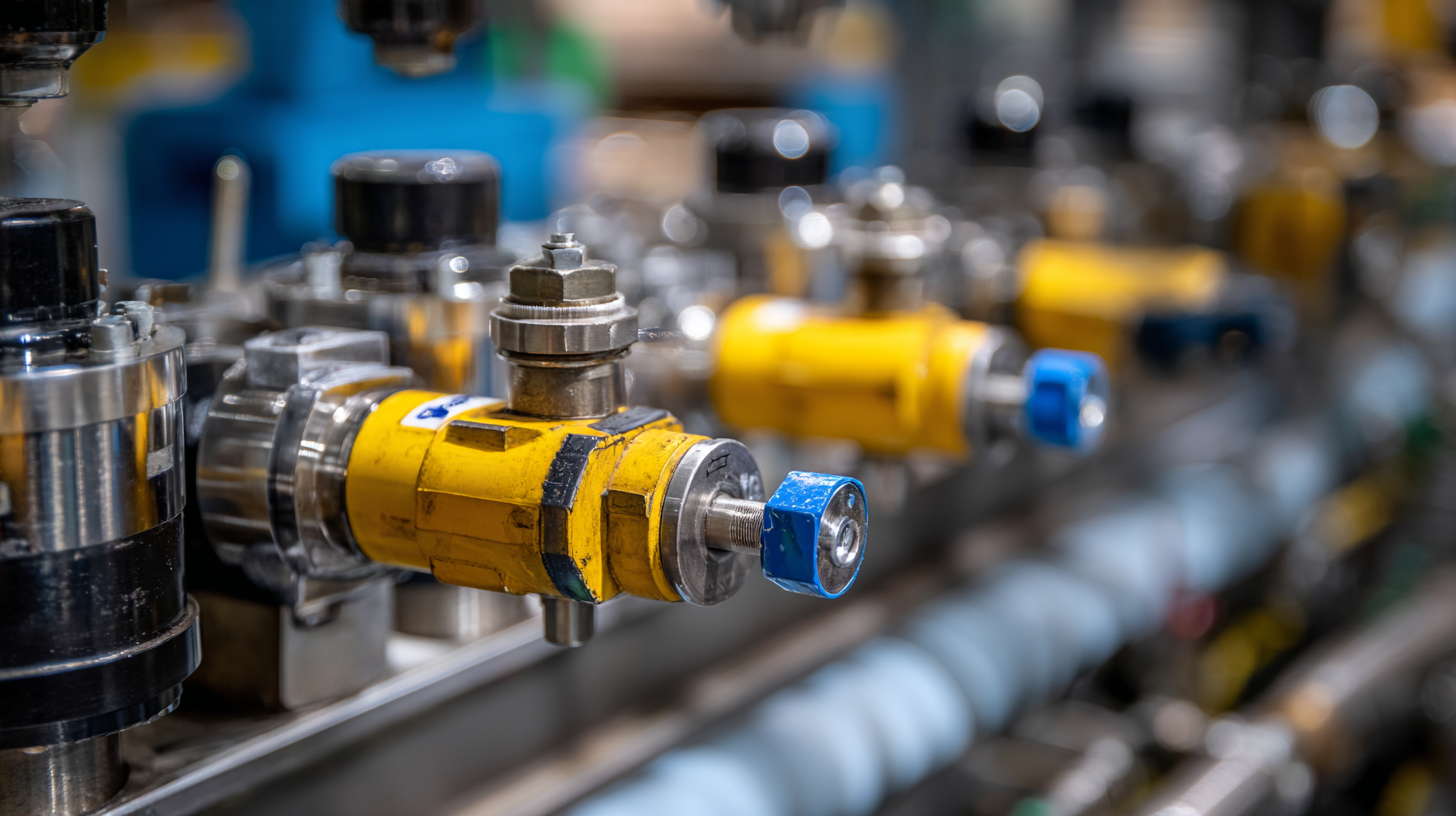

Furthermore, advancements in technology have equipped modern metering pumps with features like digital control and real-time monitoring, allowing for adjustments on-the-fly. This adaptability is crucial in applications where even minor variations can lead to significant deviations in product quality or safety. The strategic implementation of metering dosing pumps not only addresses the complexity of fluid dynamics but also underscores the critical nature of precision in ensuring industry standards are met.

| Reason | Description | Applications | Precision Level (%) |

|---|---|---|---|

| High Accuracy | Provides precise dosing across a variety of fluid types. | Chemical processing, pharmaceuticals | ±1% |

| Consistency | Ensures repeatability in fluid dosing to enhance product quality. | Food and beverage production | ±0.5% |

| Versatility | Capable of handling various fluids including viscous materials. | Oil and gas, wastewater treatment | ±2% |

| Automation Capability | Easily integrates with automated systems for enhanced control. | Manufacturing processes | ±1% |

| Reduced Waste | Minimizes spills and overuse of materials, leading to cost savings. | Chemical formulation | ±0.3% |

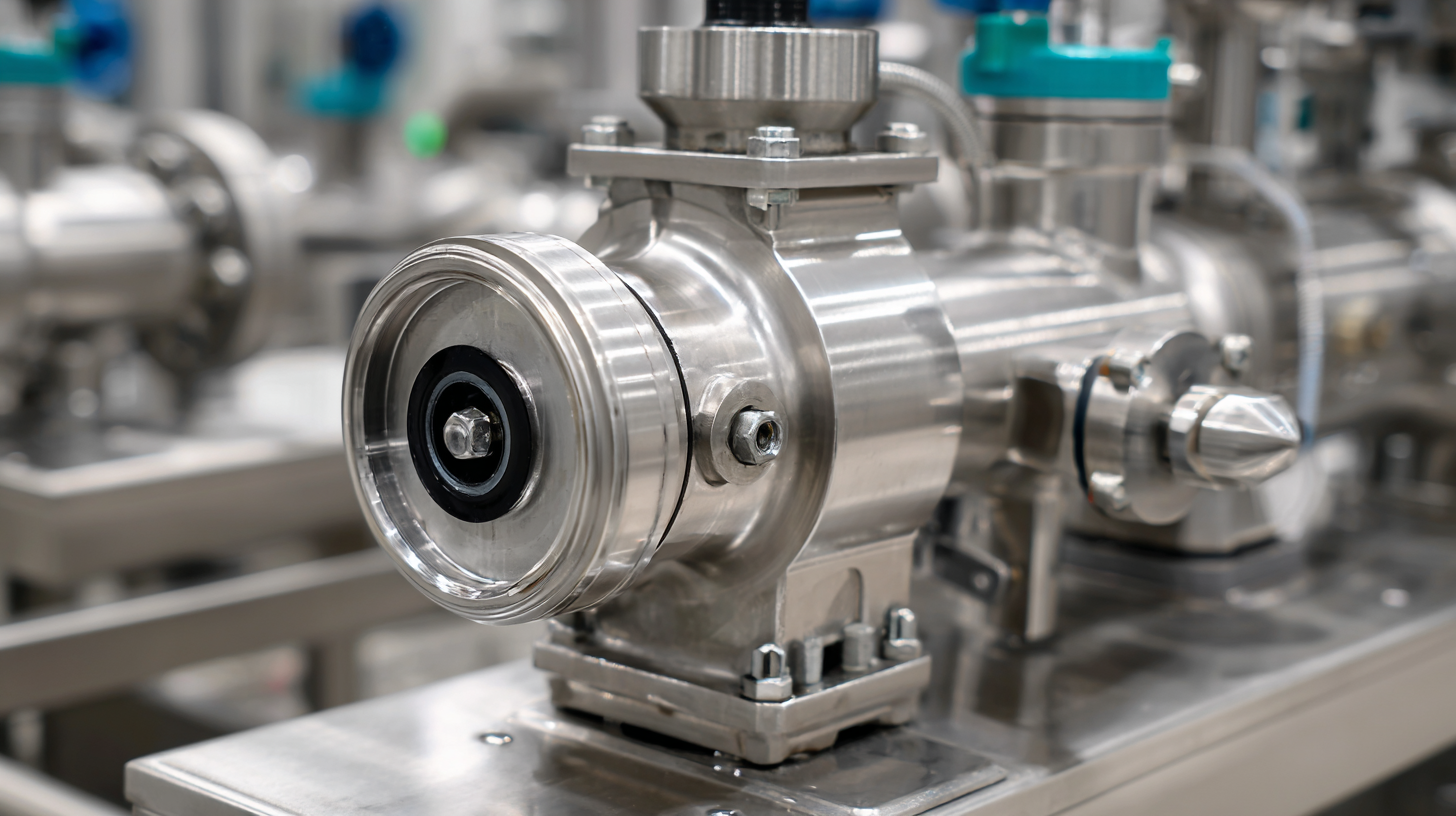

Metering dosing pumps are increasingly recognized for their essential role in precision fluid control, particularly in the pharmaceutical industry. One of their unique features is the ability to deliver exact volumes of fluids, which is crucial for ensuring consistent drug formulation and effective delivery. The precision offered by these pumps minimizes waste and optimizes the use of high-value components, thereby enhancing overall operational efficiency. This capability is vital, especially in applications involving electrospun nanofibers, where process parameters and polymer selection directly impact the final product quality.

Moreover, metering dosing pumps provide adaptable control over flow rates, enabling manufacturers to adjust to varying production needs without sacrificing accuracy. This feature is particularly relevant in the context of recent developments in electrospinning, where precise control of polymer solutions is essential for producing nanofibers with desired properties. The integration of metering dosing pumps in these processes not only improves the reproducibility of nanofiber production but also facilitates innovations in drug delivery systems, aligning with the industry's move toward more sophisticated and personalized pharmaceutical solutions.

When considering fluid control solutions, metering dosing pumps stand out for their cost efficiency and long-term benefits. One of the primary advantages is their ability to deliver precise amounts of fluid consistently, reducing waste and minimizing errors. This precision not only contributes to optimal process performance but also leads to significant savings over time. Industries can avoid over-dosing or under-dosing scenarios, which can have costly repercussions on production and resource management.

In addition to immediate savings, metering pumps offer durability and low maintenance costs, further enhancing their financial viability. Many of these pumps are designed for longevity and require minimal routine upkeep, allowing companies to allocate resources more effectively. Moreover, the energy-efficient operation of metering dosing pumps can also contribute to lower operational costs, making them a sustainable choice for fluid control. As businesses prioritize efficiency and budgeting, metering pumps prove to be a smart investment that supports both operational goals and financial health in the long run.

Metering dosing pumps play a critical role in enhancing process accuracy and consistency in various industrial applications, particularly in fluid control. Their ability to maintain steady-state accuracy ensures that the flow rate remains constant, while repeatability and linearity minimize variations during dosing. This precision is essential in industries like pharmaceuticals, where even minor deviations can lead to significant discrepancies in product quality. By adopting advanced metering pump technologies, companies can achieve improved scalability and operational efficiency, which are vital in maintaining competitiveness in the market.

The growing importance of automation further highlights the demand for metering dosing pumps, as they enable accurate and contamination-free fluid transfer. Modern advancements in pump design and control systems have made it possible to achieve higher levels of surveillance and feedback in dosing applications. As a result, industries are increasingly relying on these innovative solutions to streamline processes and boost product yield while ensuring compliance with stringent quality standards. The integration of metering dosing pumps into production systems not only enhances efficiency but also fosters greater trust in the precision and reliability of the final output.

When selecting a metering dosing pump for your application, it is essential to consider several key factors that will ensure optimal performance and reliability.

First, assess the fluid properties, including viscosity, temperature, and chemical compatibility. Different metering pumps are designed to handle specific fluid characteristics, so choosing one capable of managing your fluids effectively will enhance accuracy and prolong the pump's lifespan.

Another vital factor is the required flow rate and pressure range. Understanding the demands of your industrial processes will help narrow down the options to those that can deliver precise and consistent dosing.

Additionally, consider the pump’s control features, such as manual adjustments or digital interfaces, which can greatly improve ease of use and integration with existing systems.

By carefully evaluating these criteria, you can select the most suitable metering dosing pump that aligns with your application needs, ensuring efficient fluid control and improved operational performance.