In the realm of wastewater treatment, the efficiency of aeration systems can significantly impact operational costs and environmental sustainability. Membrane Air Diffusers have emerged as a pivotal technology in enhancing oxygen transfer efficiency in treatment facilities. According to a report by the Water Environment Federation, optimizing aeration processes can lead to energy savings of up to 30% compared to traditional mechanical systems. Furthermore, the advancement of membrane technology allows for finer bubbles, which not only increases the surface area for gas exchange but also reduces the energy required for aeration. As facility managers seek to improve both performance and cost-effectiveness, understanding the comparison of various types of Membrane Air Diffusers becomes crucial. This blog will delve into the different categories of diffusers, their operational efficiencies, and practical recommendations for selecting the best option tailored to specific wastewater treatment needs.

Membrane air diffusers play a crucial role in enhancing oxygen transfer efficiency in wastewater treatment systems. According to a study by the Water Environment Federation, the use of membrane diffusers can improve oxygen transfer rates by as much as 30% compared to traditional systems. This increase in efficiency is vital, as optimal oxygen levels are essential for the growth of aerobic microorganisms, which are responsible for breaking down organic matter in wastewater.

Moreover, advancements in diffuser technology have led to products that maintain high efficiency even under varying conditions. For instance, recent data from environmental engineering reports indicate that fine bubble diffusers can achieve oxygen transfer efficiency (OTE) rates exceeding 8 kg O2/kWh, significantly reducing energy consumption in aeration processes. This shift not only improves the overall performance of wastewater treatment systems but also aligns with sustainability goals by minimizing energy costs and greenhouse gas emissions.

In the realm of wastewater treatment, the choice of aeration technology plays a pivotal role in the efficiency of the biological decomposition process. A comparative analysis of membrane air diffusers versus traditional diffusers reveals significant differences in performance. Studies have indicated that membrane air diffusers, which produce fine bubbles, can enhance oxygen transfer efficiency by up to 30% compared to traditional coarse bubble diffusers. This increase not only optimizes the aerobic conditions necessary for the breakdown of organic compounds but also reduces energy consumption, making the treatment process more sustainable.

Moreover, research focusing on Moving Bed Membrane Bioreactors (MBMBRs) has demonstrated the advantages of employing membrane air diffusers in denitrification processes. The fine bubbles generated by these diffusers have been shown to improve the rate of nitrogen removal, achieving efficiencies that can exceed 80% under optimal conditions. This is essential in meeting stringent effluent discharge regulations and ensuring environmental protection. By leveraging the capabilities of membrane air diffusers, wastewater treatment facilities can significantly enhance their operational effectiveness while minimizing their ecological footprint.

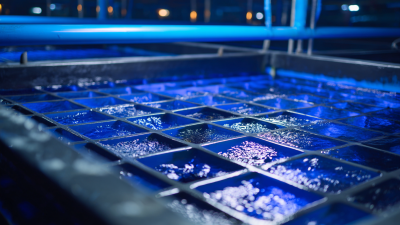

In the realm of wastewater treatment, the design of membrane air diffusers plays a crucial role in optimizing energy consumption. These diffusers, responsible for introducing air into the treatment process, can significantly influence operational efficiency and overall system performance. Recent industry insights suggest that the geometry, material, and pore size of membrane diffusers directly impact airflow rates and energy usage. For instance, innovative designs that reduce backpressure can enhance oxygen transfer efficiency while minimizing energy requirements, leading to a more sustainable operation.

Moreover, the choice of materials used for membrane diffusers is equally important. Advanced materials with superior permeation characteristics can improve gas transfer rates without significantly increasing power consumption. Balance in design ensures not only the introduction of sufficient oxygen for biological processes but also keeps energy expenditure within acceptable limits. As the industry continues to evolve, focusing on these design elements can pave the way for more efficient systems, ultimately contributing to lower operational costs and enhancing the environmental sustainability of wastewater treatment facilities.

When evaluating the performance of membrane air diffusers in various wastewater treatment scenarios, it's essential to consider several key performance metrics. One crucial aspect is the oxygen transfer efficiency (OTE), which measures how effectively diffusers transfer oxygen into the water. High OTE values indicate that the system can meet the demands of biological processes without excessive energy consumption. Testing OTE under different operating conditions, such as flow rates and mixed liquor levels, allows operators to optimize diffuser performance and maintain compliance with treatment standards.

Another important metric is the pressure drop across the diffusers, which directly influences energy consumption and operating costs. Monitoring pressure drop helps identify fouling issues and the need for maintenance, ensuring that the system operates efficiently over time. Additionally, evaluating the distribution of air bubbles generated by the diffusers offers insights into mixing patterns and overall treatment efficacy. Consistent, uniform bubble dispersion enhances contact between the wastewater and microorganisms, crucial for effective biological treatment. By focusing on these performance metrics, wastewater treatment facilities can maximize the efficiency of membrane air diffusers, leading to improved treatment outcomes and reduced operational costs.

| Treatment Scenario | Diffuser Type | Oxygen Transfer Efficiency (%) | Energy Consumption (kWh/kg O2) | Operational Cost ($/1000 m3) | Maintenance Frequency (Months) |

|---|---|---|---|---|---|

| Activated Sludge | Membrane Diffuser A | 28 | 2.5 | 120 | 12 |

| Membrane Bioreactor | Membrane Diffuser B | 30 | 2.2 | 135 | 10 |

| Sequencing Batch Reactor | Membrane Diffuser C | 27 | 2.8 | 115 | 11 |

| Trickling Filter | Membrane Diffuser D | 25 | 3.1 | 140 | 14 |

In recent years, membrane air diffusers have emerged as a transformative technology in wastewater treatment systems, significantly enhancing efficiency and performance. Case studies underline the successful implementation of these diffusers, demonstrating their ability to improve oxygen transfer rates essential for aerobic treatments. For instance, a municipal wastewater treatment facility in California reported a 30% reduction in energy costs after switching to membrane air diffusers. The fine bubble aeration provided by these diffusers not only optimized oxygen distribution but also reduced the formation of sludge blankets, leading to a more effective treatment process.

Another compelling example comes from an industrial wastewater treatment plant in Texas, where the introduction of membrane air diffusers resulted in dramatic operational improvements. The facility experienced a decrease in maintenance issues due to the self-cleaning properties of the diffusers, which minimized clogging and wear. This not only extended the lifespan of the equipment but also allowed for a more reliable and consistent treatment process. As the case studies illustrate, the strategic adoption of membrane air diffusers not only meets regulatory requirements but also fosters sustainability in wastewater management, paving the way for more eco-friendly practices in the industry.