In recent years, the demand for effective aeration solutions in wastewater treatment and aquaculture has surged, driven by the need for sustainability and efficiency. Membrane Air Diffusers have emerged as a pivotal technology in this landscape, significantly improving oxygen transfer rates and energy efficiency across various applications. According to a report from the Water Environment Federation, the implementation of advanced aeration systems, including Membrane Air Diffusers, can enhance oxygen transfer efficiency by up to 30%, leading to reduced operational costs and improved treatment performance. Furthermore, market analysis by Research and Markets indicates that the global membrane aeration market is projected to grow at a significant CAGR of 6.5% through 2027, highlighting the increasing recognition of these systems as a cornerstone for modern aeration technologies. This guide aims to delve into the numerous benefits and technical considerations associated with Membrane Air Diffusers, offering insights for engineers and stakeholders looking to optimize aeration processes.

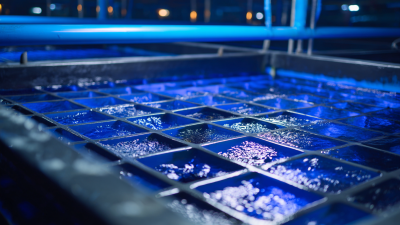

Membrane air diffusers play a crucial role in wastewater treatment and aquaculture by facilitating oxygen transfer in aeration systems. These devices come in various types, including tubular, disc, and plate diffusers, each tailored to specific applications. Tubular diffusers are often favored for their efficiency in larger treatment plants, while disc diffusers are ideal for smaller systems due to their compact design and effective oxygen distribution.

When selecting a membrane air diffuser, it's essential to consider the operational parameters of your system, such as water depth and flow rate. **Tip:** Regular maintenance and inspection of diffusers will help prolong their lifespan and ensure optimal performance. Replacing membranes before they deteriorate can significantly enhance the aeration efficiency of the entire system.

Another important aspect is the materials used in membranes, as this can affect durability and performance in various conditions. **Tip:** Look for diffusers made from high-quality, resistant materials that can withstand fouling and wear over time. This will not only improve aeration rates but also minimize downtime for maintenance. Understanding these different types and their specific applications will enable you to make informed decisions, ultimately enhancing the effectiveness of your aeration systems.

Membrane air diffusers play a pivotal role in enhancing aeration systems, particularly due to their ability to effectively transfer oxygen in wastewater treatment processes. The utilization of fine bubble diffusers has been shown to enhance the oxygen transfer rate significantly, overcoming the limitations posed by the low solubility of oxygen in water. With advancements in Computational Fluid Dynamics (CFD), modeling these aeration systems has become more refined, allowing for a better understanding of fluid behavior and oxygen dynamics, ultimately paving the way for improved treatment outcomes.

Moreover, the performance of membrane bioreactors (MBRs) is notably influenced by the aeration methods employed. Recent experimental studies reveal that coarse bubble aeration can help mitigate membrane fouling, which is a common challenge in high-loaded systems. This capability of coarse bubbles to reduce the formation of cake layers enhances the overall efficiency of MBR systems while contributing to better pollutant removal and energy consumption. As the industry continues to evolve, membrane air diffusers remain at the forefront of innovative solutions in wastewater treatment, showcasing their key advantages in maintaining sustainable and effective aeration systems.

In wastewater treatment, the aeration process is pivotal for fostering biological decomposition of organic matter. Membrane air diffusers have emerged as a highly efficient solution to enhance aeration systems, leading to improved treatment outcomes. According to a report by the Water Environment Research Foundation, optimizing aeration can increase the overall efficiency of a wastewater treatment facility by 15-30%. This efficiency is largely attributed to the fine bubble aeration that membrane diffusers provide, which maximizes the contact area between air and water, thus improving oxygen transfer rates.

When it comes to installation techniques for membrane diffusers, proper placement and alignment are crucial for achieving optimal performance. It is recommended that diffusers be installed at an appropriate depth, typically between 2 to 4 meters, to minimize foaming and maximize oxygen absorption. Furthermore, maintaining a consistent spacing between diffusers facilitates a uniform distribution of air, which enhances the overall efficacy of the aeration system. Regular maintenance and inspection also play a vital role in ensuring that the diffusers operate at peak performance levels, as indicated by industry data suggesting that well-maintained systems can lead to a reduction in energy consumption by up to 20%.

Proper maintenance of membrane air diffusers is essential for maximizing their lifespan and maintaining the efficiency of aeration systems. According to a report from the Water Environment Federation, regular inspection and cleaning of diffusers can lead to a 20-30% increase in operational efficiency. This not only enhances the oxygen transfer rate but also reduces energy consumption, making it imperative for facility managers to prioritize maintenance practices.

In addition to routine cleaning, it is important to monitor the condition of the membranes, as wear and tear can significantly affect performance. A study conducted by the American Society of Civil Engineers highlights that replacing damaged or worn membranes in a timely manner can prevent costly downtime and ensure that systems operate at peak performance. Implementing preventive maintenance schedules, including checking for leaks and damage, has been shown to extend the life of membrane air diffusers by up to 50%. Incorporating these best practices not only improves system longevity but also ensures compliance with environmental regulations and enhances overall system reliability.

When dealing with membrane air diffusers, troubleshooting common issues is essential to maintain optimal performance in aeration systems. One frequent problem is the clogging of membranes, which can significantly reduce air transfer efficiency. Clogs often occur due to the accumulation of biological sludge or particulate matter. Regular inspection and cleaning of diffusers can help prevent this issue. Employing a backwashing system or occasionally replacing the membranes may also be necessary to ensure consistent airflow and prevent deterioration.

Another common challenge is uneven air distribution, which can lead to suboptimal aeration in treatment processes. Factors such as incorrect installation, varying water depths, and fluctuating air pressures can contribute to this issue. It's crucial to check the alignment and condition of the diffuser plates as well as ensure the aeration tank is designed to accommodate uniform air flow. Adjusting the air supply system or using flow control valves can also mitigate these problems, promoting balanced aeration across the entire system. Regular monitoring and data analysis are key to preemptively addressing these issues before they affect overall system performance.