In the realm of industrial applications, the efficiency of solid-liquid separation processes is paramount, and the Dewatering Press Machine plays a crucial role in achieving optimal results. As industries seek to enhance productivity while minimizing environmental impact, selecting the right dewatering press can significantly influence operational costs and output quality. This ultimate guide aims to provide a comprehensive comparison of various dewatering press machines available on the market. By examining key features, performance metrics, and suitability for diverse applications, readers will gain valuable insights into making informed decisions.

Whether you are involved in wastewater treatment, food processing, or any other sector requiring effective dewatering solutions, understanding the nuances of different machines will empower you to select the most appropriate technology for your specific needs. Join us as we delve into the intricacies of dewatering press machines and uncover the best options tailored for your industrial endeavors.

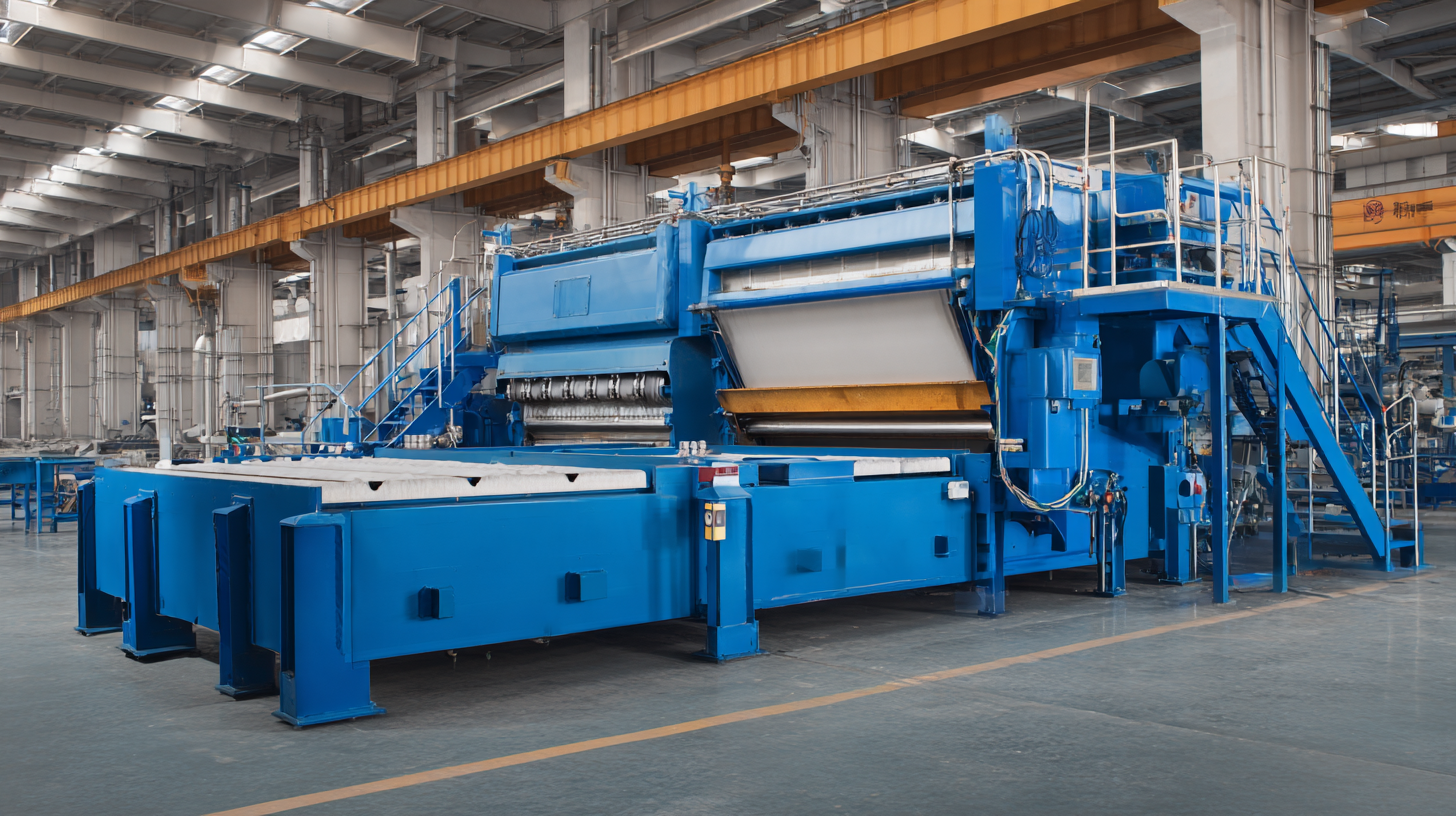

Dewatering press machines are essential in various industrial applications, designed to remove water from sludges and similar materials. Understanding their key components and functionality is vital for selecting the right machine for your specific needs. At the heart of these machines is the pressing mechanism, which applies significant force to the material, facilitating moisture extraction. This process is often enhanced by the use of filter plates and cloths that separate solids from liquids, ensuring maximum efficiency during operation.

Another critical component of dewatering press machines is the control system, which regulates pressure and processing times. Modern machines incorporate advanced sensors and automation technology to optimize performance, reduce energy consumption, and minimize human error. Additionally, the structural design of these machines can vary, affecting their capacity and efficiency in handling different types of materials. Familiarizing oneself with these components not only aids in making informed purchasing decisions but also contributes to improved operational effectiveness in water-intensive industries.

When considering dewatering press technologies for industrial applications, it's crucial to understand the various options available and their respective advantages. The comparative analysis of these technologies reveals that mechanical, thermal, and chemical methods each offer unique benefits suited to different industrial needs. For instance, mechanical dewatering presses typically excel in operations where solid-liquid separation is required without the use of chemicals, making them ideal for food processing and wastewater treatment.

Tip: Always evaluate the specific materials you will be processing, as some dewatering technologies are more suited to certain types of sludge or waste. This can significantly impact the efficiency and cost-effectiveness of your dewatering solution.

Additionally, incorporating automation in the dewatering process can enhance operational efficiency and reduce labor costs. Technologies that support real-time monitoring and process control provide users with valuable data insights, enabling better decision-making and optimization of the dewatering cycle.

Tip: Invest in systems that allow for easy integration with existing processes to streamline operations and maximize resource utilization, ensuring a smoother transition to enhanced dewatering methods.

When evaluating the efficiency of dewatering press machines, performance metrics play a crucial role in determining suitability for industrial applications. Key performance indicators such as extraction rate, cake dryness, and energy consumption are vital for assessing how effectively a machine can remove moisture from sludge or other materials. A higher extraction rate signifies a more efficient dewatering process, while the cake's moisture content is essential for meeting disposal or processing requirements.

Understanding these metrics helps industries select the right machine that can balance operational costs with performance outcomes.

Another critical aspect of evaluating dewatering press machines is their adaptability to different materials and operational conditions. Machines equipped with advanced control systems offer greater flexibility and can adjust processing parameters in real-time, leading to improved performance. Additionally, maintenance requirements and the machine's lifespan are invaluable metrics, as they can directly affect long-term operational efficiency and cost-effectiveness. By closely examining these performance metrics, industries can make informed decisions that enhance productivity and reliability in their dewatering processes.

When considering the purchase of a dewatering press for industrial applications, cost is a critical factor that can significantly impact your operation's budget and long-term profitability. Investing in the right dewatering press means not only evaluating the initial purchase price but also considering operational costs, maintenance expenses, and the potential return on investment. A higher upfront cost might be justifiable if the machine offers superior efficiency, durability, and reduced operating costs over time.

Furthermore, it’s essential to assess the specific needs of your operation. Different industries require varying features; therefore, understanding your process requirements can help in selecting a machine that optimally balances cost and functionality. The right dewatering press can lead to lower waste disposal costs, improved product quality, and increased throughput. Thus, a thorough comparison of various models and their long-term financial implications can ultimately guide you to make an informed investment that aligns with your operational goals.

| Dewatering Press Type | Capacity (kg/hr) | Power Consumption (kW) | Estimated Cost ($) | Maintenance Frequency (months) |

|---|---|---|---|---|

| Belt Press | 1000 | 5 | 20,000 | 6 |

| Screw Press | 800 | 4 | 25,000 | 12 |

| Plate and Frame Press | 1200 | 6 | 30,000 | 8 |

| Centrifugal Press | 1500 | 7 | 35,000 | 10 |

Proper maintenance of dewatering press equipment is crucial for enhancing its efficiency and longevity. According to a recent report by the International Society for Industrial Solutions, regular maintenance can increase equipment lifespan by up to 30%. This emphasizes the importance of not only routine checks but also in-depth examinations of moving parts and seals to ensure they function optimally.

Tips: Schedule bi-weekly inspections to catch potential issues early. Look for signs of wear such as leaks or unusual noises that could indicate a need for repair.

Incorporating best practices for maintenance is key. For instance, maintaining a clean operating environment significantly reduces the risk of contaminants affecting the performance of the machine. Statistics show that a clean workspace can decrease failure rates by up to 25%. Regularly cleaning filters and monitoring fluid levels also contributes to the overall health of the dewatering press.

Tips: Establish a cleaning protocol that includes daily, weekly, and monthly tasks to ensure the equipment stays in peak condition. Additionally, training staff on these maintenance measures can lead to a more proactive approach to equipment care.