The demand for efficient and sustainable wastewater treatment technologies has never been greater, as urbanization and industrial growth continue to escalate. Membrane Air Diffuser technology has emerged as a leading solution in this field, reflecting significant advancements in aeration systems. According to a report by the Global Water Intelligence, the wastewater treatment market is expected to reach $400 billion by 2025, with innovations like Membrane Air Diffuser contributing to improved energy efficiency and operational performance. These diffusers are renowned for their ability to maximize oxygen transfer efficiency while minimizing maintenance costs and energy consumption. The U.S. Environmental Protection Agency highlights that aeration typically accounts for 50-60% of the energy used in treating wastewater; thus, the adoption of Membrane Air Diffuser technology can lead to substantial reductions in energy expenditure and carbon footprint, ultimately promoting more sustainable practices in wastewater management.

The demand for efficient and sustainable wastewater treatment technologies has never been greater, as urbanization and industrial growth continue to escalate. Membrane Air Diffuser technology has emerged as a leading solution in this field, reflecting significant advancements in aeration systems. According to a report by the Global Water Intelligence, the wastewater treatment market is expected to reach $400 billion by 2025, with innovations like Membrane Air Diffuser contributing to improved energy efficiency and operational performance. These diffusers are renowned for their ability to maximize oxygen transfer efficiency while minimizing maintenance costs and energy consumption. The U.S. Environmental Protection Agency highlights that aeration typically accounts for 50-60% of the energy used in treating wastewater; thus, the adoption of Membrane Air Diffuser technology can lead to substantial reductions in energy expenditure and carbon footprint, ultimately promoting more sustainable practices in wastewater management.

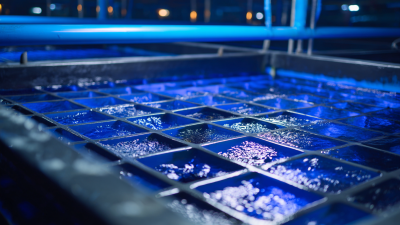

Membrane air diffuser technology is transforming the landscape of wastewater treatment, significantly enhancing operational efficiency. By introducing fine bubbles into the wastewater, these diffusers optimize the aeration process, ensuring that oxygen is efficiently transferred to microorganisms.

This process not only accelerates the degradation of pollutants but also minimizes energy consumption. As a result, facilities can achieve higher levels of treatment with lower operational costs, making it a smart choice for wastewater management.

Tips for choosing the right membrane air diffuser include considering the size and configuration of your treatment system. Ensuring that the diffuser type aligns with your specific needs—such as flow rate and desired oxygen transfer efficiency—is crucial. Additionally, routine maintenance and monitoring can prolong the lifespan of your diffusers, ensuring consistent performance over time.

Investing in membrane air diffuser technology can yield substantial improvements in wastewater treatment. Facilities that adopt this technology often see enhancements in both their treatment capacity and discharge quality. Emphasizing continuous optimization through effective system design and durable materials can drive long-term sustainability in wastewater management practices.

Membrane air diffuser technology has revolutionized aeration systems in wastewater treatment by significantly increasing energy efficiency. Traditional aeration methods often lead to excessive energy consumption, primarily due to the inefficient transfer of oxygen from air to water. However, membrane air diffusers utilize finer bubbles that enhance oxygen transfer rates and reduce energy input. This innovation not only contributes to effective treatment of wastewater but also aligns with sustainability goals by lowering overall operating costs.

Furthermore, the implementation of membrane air diffusers can lead to substantial annual energy savings. By optimizing the aeration process, these diffusers require less electricity to maintain necessary dissolved oxygen levels, which is a pivotal factor in biological treatment processes. Quantitative studies have shown that facilities employing membrane air diffusion systems can achieve energy savings of up to 30% compared to conventional aeration methods. This reduction in energy consumption not only benefits the environment by decreasing greenhouse gas emissions but also provides economic relief for plants striving to manage escalating energy costs in the wastewater treatment industry.

Membrane air diffusers have emerged as a modern solution in wastewater treatment, particularly when compared to traditional air diffuser systems. One of the primary advantages of membrane air diffusers is their ability to provide finer bubble distribution, leading to enhanced oxygen transfer efficiency. This finer diffusion allows for a larger surface area contact between air and wastewater, resulting in improved biological treatment processes. In contrast, traditional air diffusers typically produce larger bubbles that can rise quickly, reducing contact time and overall efficiency.

Another significant benefit of membrane air diffusers is their lower energy consumption. Because of their effective oxygen transfer capabilities, membrane systems often require less air flow to achieve the same treatment outcomes as traditional systems. This reduction in energy usage not only lowers operational costs but also contributes to a more sustainable approach to wastewater management. Additionally, membrane diffusers are generally easier to maintain, with fewer clogging issues compared to traditional designs. This reliability and efficiency make them an attractive option for facilities looking to optimize their wastewater treatment processes.

Membrane air diffuser technology plays a crucial role in advancing wastewater treatment practices, particularly in reducing sludge generation and treatment costs. As the global water and wastewater treatment market is anticipated to grow from $346.41 billion in 2024 to $617.81 billion by 2032, at a compound annual growth rate of 7.5%, the effective management of sludge becomes increasingly important. Traditional methods of wastewater treatment often result in high sludge production, which can escalate treatment costs and environmental impacts.

The introduction of membrane air diffusers enhances the aeration process, promoting more efficient oxygen transfer while minimizing energy consumption and overall operational costs. By optimizing aeration, wastewater treatment plants can significantly decrease the volume of sludge generated. This advancement not only supports the industry's goal to meet the ambitious targets set forth in the "14th Five-Year Plan" but also aligns with innovative sustainable practices that can transform waste into valuable resources. As the technology evolves, it stands to foster a circular economy in wastewater management, thereby paving the way for a greener future.

Membrane air diffuser technology offers significant advantages in wastewater treatment, particularly in meeting environmental compliance and regulatory standards. This technology enhances oxygen transfer efficiency, which is crucial in the biological treatment processes of wastewater. By supplying fine bubbles generated through the membrane, it ensures optimal oxygen levels for aerobic microorganisms, thereby improving the breakdown of contaminants. As a result, facilities employing membrane air diffusers can achieve better effluent quality, which is essential for complying with stringent environmental regulations.

Moreover, the implementation of membrane air diffusers contributes to energy efficiency in wastewater treatment plants. Traditional aeration systems often lead to high operational costs due to energy consumption. In contrast, membrane diffusers require lower energy inputs while maximizing the treatment efficiency. This alignment with regulatory demands for reduced energy usage not only helps facilities meet compliance but also supports sustainability goals. Consequently, the adoption of membrane air diffuser technology represents a proactive approach to environmental stewardship, enabling wastewater treatment facilities to address both compliance and operational challenges effectively.