In today's fast-paced industrial environment, optimizing operations and improving efficiency have become critical for businesses across various sectors. A substantial report by the World Bank suggests that industries leveraging advanced dewatering technologies can achieve up to a 30% reduction in water usage and a significant decrease in waste management costs. Among these technologies, the Dewatering Press stands out as a powerful solution that not only enhances the separation of liquids and solids but also contributes to environmentally sustainable practices. By utilizing a Dewatering Press, organizations can ensure higher material recovery rates, reduced disposal costs, and improved overall productivity. As companies strive for operational excellence, adopting such innovative equipment presents an invaluable opportunity to streamline processes and maximize resource efficiency.

In today's fast-paced industrial environment, optimizing operations and improving efficiency have become critical for businesses across various sectors. A substantial report by the World Bank suggests that industries leveraging advanced dewatering technologies can achieve up to a 30% reduction in water usage and a significant decrease in waste management costs. Among these technologies, the Dewatering Press stands out as a powerful solution that not only enhances the separation of liquids and solids but also contributes to environmentally sustainable practices. By utilizing a Dewatering Press, organizations can ensure higher material recovery rates, reduced disposal costs, and improved overall productivity. As companies strive for operational excellence, adopting such innovative equipment presents an invaluable opportunity to streamline processes and maximize resource efficiency.

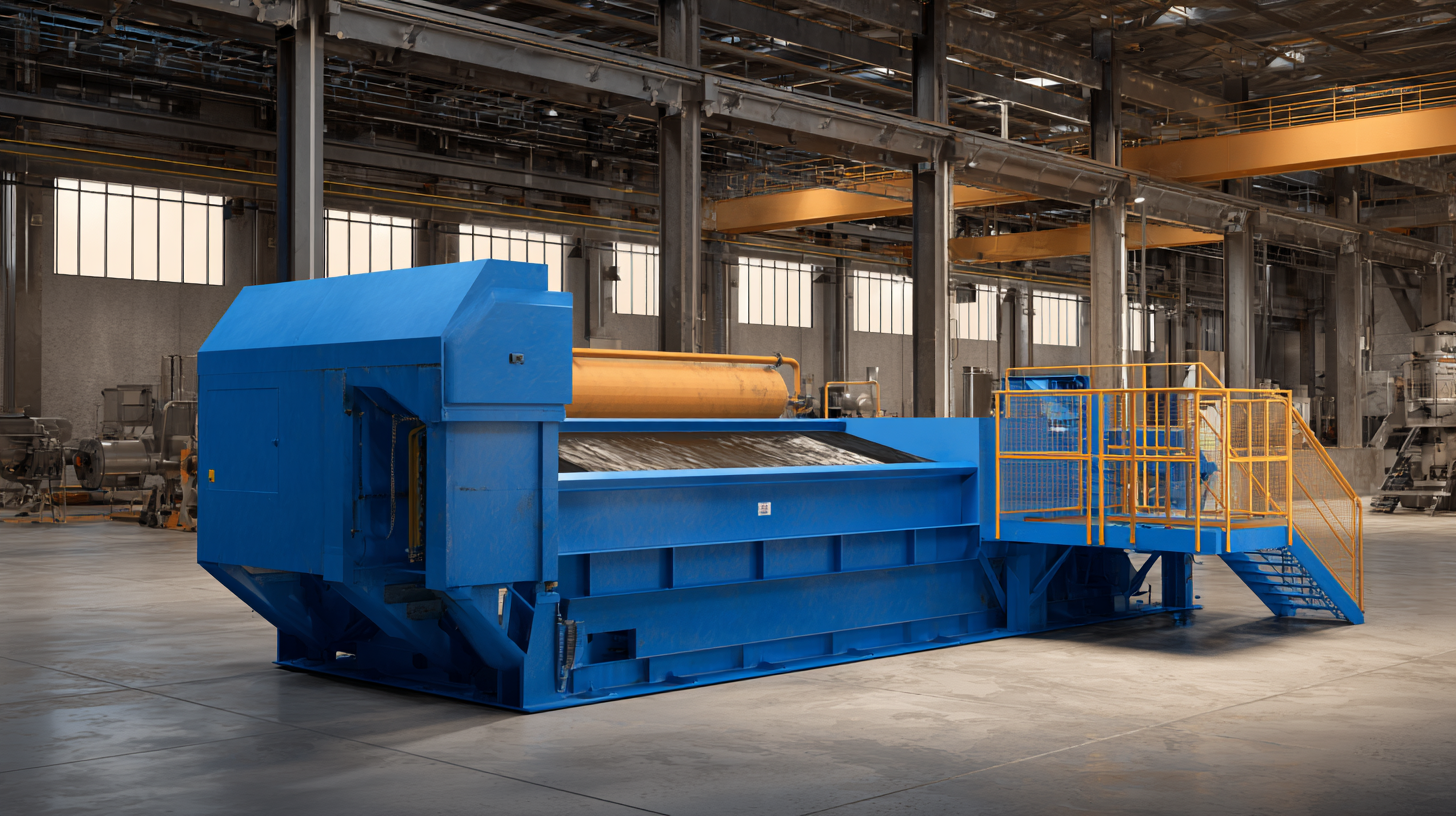

Dewatering presses have emerged as powerful tools in optimizing sludge treatment processes across various industries, particularly in wastewater management. Understanding the technology behind dewatering presses can enhance operational efficiency while addressing the pressing issues posed by large quantities of sludge generated by treatment plants. These machines utilize advanced mechanisms to separate water from sludge, ensuring a drier product that is easier to handle and dispose of, thereby reducing overall waste management costs.

Recent advancements in dewatering technology have showcased multiple methods, including the use of screw presses and rotary presses, each offering unique benefits. For instance, implementing tips for improved dewatering can lead to drier cake solids concentration. Experts suggest focusing on the right press design and maintaining equipment meticulously to enhance efficiency. Attention to proper maintenance routines can mitigate issues such as feed screw and barrel wear, thus extending the life of the equipment and maintaining performance standards.

Furthermore, exploring alternative uses for dewatered sludge can drive additional value for operations. From turning sludge into resources for energy production to its application in agricultural endeavors, these innovative practices highlight the potential of effective dewatering technology in not just waste reduction, but also in resource recovery. By embracing these technologies and insights, industries can achieve more sustainable operations in their handling of wastewater byproducts.

Dewatering presses have emerged as a superior solution in waste management and material processing, particularly when compared to traditional methods such as centrifugation and gravity drainage. According to a recent industry report by Grand View Research, the global dewatering equipment market is projected to reach $6.8 billion by 2025, demonstrating a clear shift towards more efficient technologies. The advantages of dewatering presses are particularly evident in their ability to reduce sludge volumes by up to 90%, thereby significantly decreasing transportation and disposal costs.

Moreover, these presses offer enhanced energy efficiency, consuming up to 50% less energy than conventional dewatering methods. A study published in the Journal of Environmental Management highlighted that facilities utilizing dewatering presses experienced lower operational costs and improved environmental compliance rates, primarily due to reduced chemical use and lower greenhouse gas emissions. The ability to automate the dewatering process further increases throughput while minimizing labor costs, making dewatering presses an attractive option for industries ranging from wastewater treatment to food processing.

In the realm of industrial operations, the choice of dewatering solutions can significantly impact both efficiency and costs. Among the various options available, dewatering presses stand out due to their remarkable cost-effectiveness. Unlike traditional methods that often require extensive labor and bulky equipment, a dewatering press streamlines the process, reducing the overall operational expenses. By consolidating the dewatering and filtration phases into a single, automated system, organizations can lower their energy consumption and minimize waste disposal costs.

Furthermore, a financial comparison of dewatering solutions reveals that the upfront investment in a dewatering press is often offset by the long-term savings it generates. With lower maintenance requirements and a decrease in the volume of sludge produced, businesses can realize substantial reductions in both operational costs and landfill fees. Additionally, the ability to achieve higher solid recovery rates further enhances profitability, as companies can repurpose or sell the dehydrated material, turning a potential expense into a revenue stream.

As industries seek more sustainable and economically viable solutions, the dewatering press emerges as a robust contender in enhancing operational efficiencies while maintaining cost-effectiveness.

Dewatering presses have become essential tools in various industries, particularly for enhancing operational efficiency. These machines effectively remove excess water from sludges and waste materials, leading to reduced disposal costs and improved resource recovery. By increasing the solid content of the processed materials, businesses can streamline their operations, conserve energy, and maximize overall output, making it a key investment for enhancing productivity.

Tip: Regular maintenance is crucial to ensure optimal performance of your dewatering press. Check the hydraulic systems and replace any worn-out parts to prevent unexpected downtimes and maintain efficiency.

Moreover, implementing a dewatering press can significantly speed up the material processing times. As water is eliminated more rapidly, businesses can handle larger volumes of waste without compromising on quality. This not only boosts productivity but also helps companies meet strict environmental regulations more effectively.

Tip: Train your operators on best practices for using the dewatering press to ensure they understand the machine's capabilities and limitations. Proper training can lead to higher operational efficiency and better safety practices in the workplace.

The environmental impact of dewatering processes is a critical factor in sustainable operations, particularly in the mining and resource recovery industries. The efficient management of fine phosphate tailings (FPTs) not only helps conserve water resources but also reduces potential environmental risks associated with excessive water loss and tailings dam stability. A study reveals that utilizing advanced flocculating agents such as xanthan gum, sodium alginate, and carboxymethyl cellulose significantly enhances the dewatering performance of FPTs, leading to improved water recovery rates while minimizing ecological footprints.

Moreover, the U.S. sludge thickening and dewatering equipment market, valued at approximately USD 672.9 million in 2024, is expected to grow steadily, reflecting increased investments in sustainable technologies. As industries look for ways to mitigate their environmental impact, implementing innovative dewatering systems can aid in achieving sustainability goals, particularly in operations like copper extraction where underground water challenges must be addressed.

**Tips:** Consider leveraging eco-friendly flocculants to enhance water recovery and reduce biochemical impacts. Regular maintenance of dewatering equipment can enhance efficiency and prolong lifespan, ensuring optimal performance in environmentally-sensitive operations.